Westinghouse Employee Newsletter (September 1943)

Item

Title

Westinghouse Employee Newsletter (September 1943)

Description

Volume One, September 1943, Number Seven

2

Wherever super cleanliness is vital to health - in hospitals, restaurants, food industries, etc., the Westinghouse Sterilamp is doing a man-size job. Its rays spell doom for germs. In our cafeteria (above) a Sterilamp constantly stands guard over the cutlery.

THE DEATH RAY THAT GUARDS LIFE

Westinghouse is fighting two wars at once. Everyone knows about the many types of weapons manufactured here for effective use against the Nazis. But few are aware that fixtures and bulbs for the Sterilamp, which protects health by killing germs, are made in the West End Plant.

The Sterilamp wars against bacteria on many fronts. By producing strong ultra-violet rays it does its biggest health job in hospitals. Infections which formerly occurred after major operations are now controllable through installation of these wonder lamps over operating tables. Sanitary conditions are similarly maintained in food industries, laboratories engaged in the preparation of essential vaccines, restaurants, meat stores, etc.

In appearance, the Westinghouse Sterilamp is a slender rod-shaped glass tube, flaring slightly at each end where the electrodes are located. Sterilamps operate on alternating current through the medium of current regulating transformers.

Although installations are restricted for the duration to essential industries and services, many new uses for the Sterilamp are anticipated in post-war years. A device that guards public health by killing germs in the millions deserves a bright future.

INFLATION WILL GET US IF WE DON’T WATCH OUT

Those of us who remember the last war have vivid recollections of how high the prices of common things soared. In Hamilton, for instance, butter sold for 65c, a pound, sugar for 29c potatoes for $1.22 a ten-pound bag, and work boots, which were very often of only imitation leather, were $12.00 a pair. In fact, in those days, we paid nearly twice as much as we are paying for the same articles today, and to add to the difficulties, there was a shortage of practically everything, which, in turn, resulted in higher prices being demanded.

You see, people were making very high wages- more money in fact than they could spend in wartime- and with the surplus money they were continually striving to outbid each other for the scarce goods. This forced the prices up, which necessitated an increase in wages. Thus, alternately, prices and wages went higher and higher, with the wages never quite catching up- always coming out second best. The Government in that day took no effective steps to prevent this trend.

That is inflation. True, it wasn’t called by that name in the last war, but it has occured- to a great or less degree- during every war period.

Of course, all of us would like to have more money. Actually what we want is to be able to purchase more goods- to improve our standard of living. Under conditions of inflation, however, getting more money does not improve the standard of living, since an increase in wages results in an increase in the price of goods which is greater in proportion than the wage increase. Thus, the standard of living is actually lowered.

This is what happened in the last war and is what the Government is now trying to prevent by rationing scarce goods, putting a ceiling price on necessary goods, stabilizing wages, providing a Cost-of-Living Bonus, and increasing taxes.

But the Government cannot accomplish this great task alone. It takes the co-operation of every individual to make it an actual success. The Government can’t prevent inflation unless you- and you- and I are willing to undertake to carry out those things which are necessary to prevent it.

THe first requirement is to purchase only those things which we need. It is true that the temptation is great to purchase those things which we have wanted - but not actually needed- for a long time, especially when we have a bit of extra money in hand. If we confine our purchases to our needs, there will be enough of everything to go around.

Secondly, if we refuse to pay more than a fair price for what we buy, and ask only a fair price for what we have to sell- be it goods or labour- prices are bound to stay where they are at present.

Then with our surplus money, there are the old debts and mortgages to be paid off, life insurance to buy, bank accounts to be increased and Victory Bonds to purchase, and when the war is over, the slate will be clean- no bad debts, no things that have to be settled. However, there will be a “nest egg” of considerable size that we will be free to spend on long-desired luxuries, to make a down payment on a new home, or to give our boys and girls an education. All industry, freed from war production, can thus be concentrated on providing goods for the civilian population, and give full employment to thousands to supply the demand for those articles which we have done without in wartime.

We shall then have paid for the war as we went along, kept all fronts supplied with necessities, and ensured stability of our currency by preventing inflation.

John R Reed

President

3

Westinghouse Employees Magazine

Vol. 1, No. 7 September, 1943

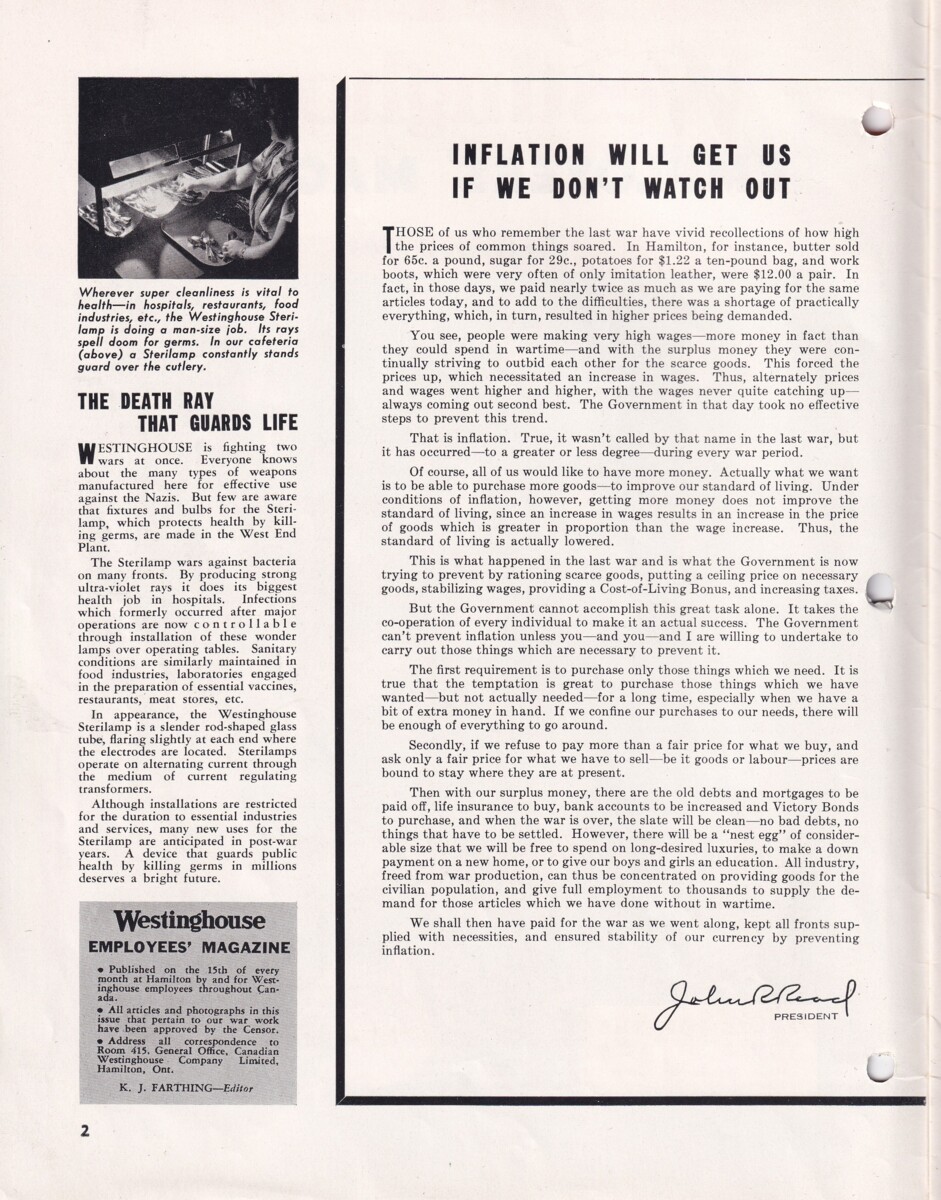

“THERE’S NOTHING TO IT”

…say Westinghouse Employees who regularly contribute their blood to the Red Cross Blood Bank.

Just one of the gang, Albert Hawkins (WX Department) has donated blood to the Red Cross 22 times! “Nothing to it”, he says.

What would you do if your next door neighbour suddenly took ill and needed a blood transfusion? “Why,” you say, “I’d go right to the hospital and offer to give my blood.”

Now your next door neighbour’s son may be in the Armed Forces. He may be wounded and in need of a blood transfusion this very minute. Of course you can’t rush to his aid overseas as you would to his Dad who lives next door.

But like 1,000 fellow Westinghouse workers you can become a Blood Donor and thus make sure that no Canadian soldier will ever die for want of a blood transfusion.

Being a Blood Donor is easy. There’s absolutely nothing to it. Look at the pictures on this page for definite proof. We’ll just say this: There are 10,000 Blood donors in Wentworth County. Of this number one-tenth are Westinghouse people who have been organized in a great humanitarian cause mostly through the efforts of B. B. Hodge, Personnel Manager.

Let’s keep up the good work. See your Foreman today about becoming a Blood Donor. Your blood may save a Canadian soldier’s life. (Continued on page 15)

Off we go. Pretty Red Cross driver, Margaret Ambrose is about to whisk these smiling chaps off to the Blood clinic. Shown are Blood DOnors George Worthingham (No. 2 Store Room), Joe De FOrest (BX), Joe Harrison (B6), Dave McKay (A2), Terrence Brady (D5) and George Greenaway (BX).

“Your name please?” asks Miss Margaret Templin and the Westinghouse Blood Donor answers “Dave McKay, A2”. Other donors wait to register.

Temperature taking: The nurse places a thermometer in each man’s mouth. Regular Donors, they relax knowing that there’s nothing to it.

“No change in health?” asks Dr. Crack as Joe De Forest (BX) takes a Hemoglobin Test and Mrs. Radcliffe checks the record. WHat happens next is shown on page 15.

4

Our Years of Tool Making Experience has Proved Invaluable in the Switchover of Production from Peace to War.

TOOLS

FOR THE TOOLS OF WAR…

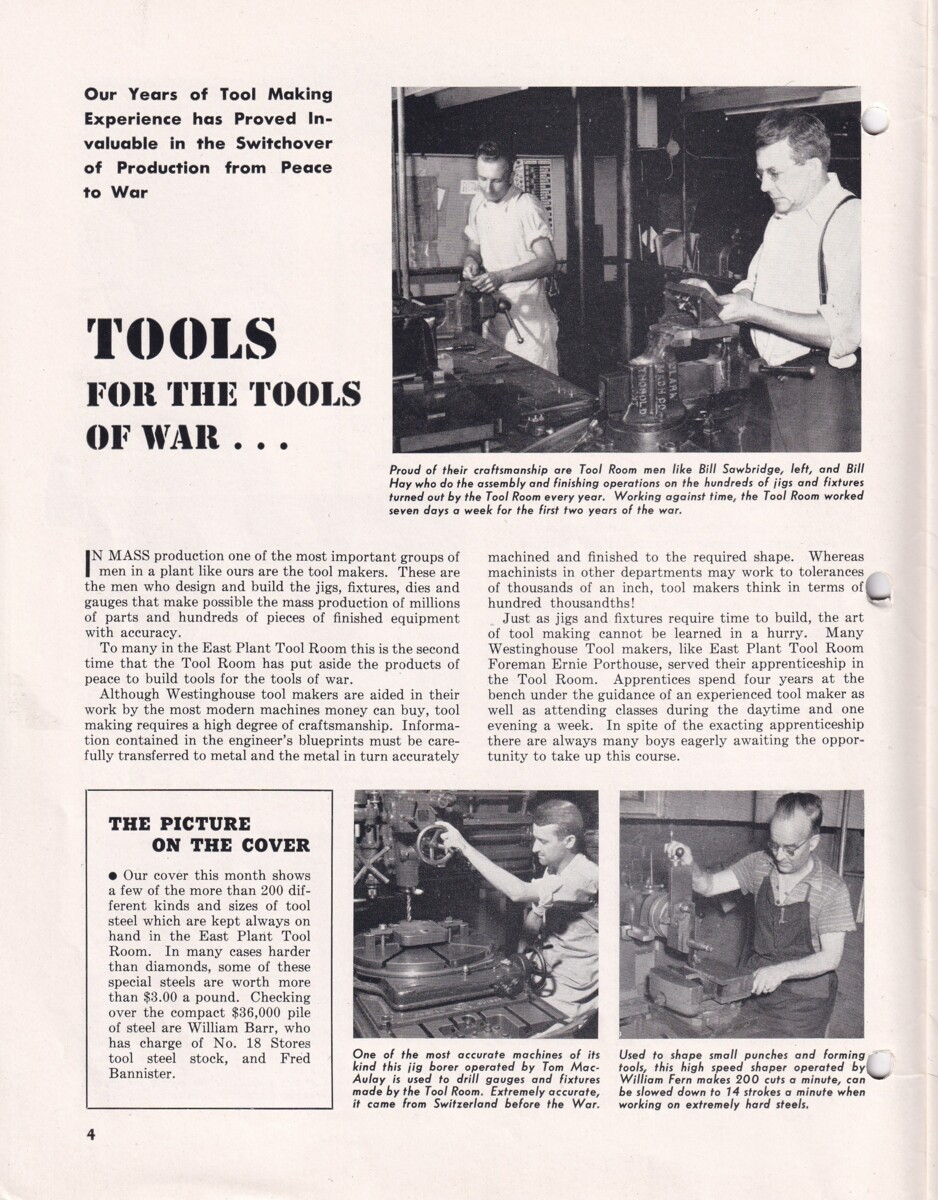

Proud of their craftsmanship are Tool Room men like Bill Sawbridge, left, and Bill Hay who do the assembly and finishing operations on the hundreds of jigs and fixtures turned out by the Tool Room every year. Working against time, the Tool Room worked seven days a week for the first two years of the war.

In mass production one of the most important groups of men in a plant like ours are the tool makers. These are the men who design and build the jigs, fixtures, dies and gauges that make possible the mass production of millions of parts and hundreds of pieces of finished equipment with accuracy.

To many in the East Plant Tool ROom this is the second time that the Tool Room has put aside the products of peace to build the tools for the tools of war.

Although Westinghouse tool makers are aided in their work by the most modern machines money can buy, tool making requires a high degree of craftsmanship. Information contained in the engineer’s blueprints must be carefully transferred to metal and the metal in turn accurately machined and finished to the required shape. Whereas machinists in other departments may work to tolerances of thousands of an inch, tool makers think in terms of hundred thousandths!

Just as jigs and fixtures require time to build, the art of tool making cannot be learned in a hurry. Many Westinghouse Tool makers, like East Plant Tool Room Foreman Ernie Porthouse, served their apprenticeship in the Tool Room. Apprentices spend four years at the bench under the guidance of an experienced tool maker as well as attending classes during the daytime and one evening a week. In spite of the exacting apprenticeship there are always many boys eagerly awaiting the opportunity to take up this course.

One of the most accurate machines of its kind is this jig borer operated by Tom MacAulay is used to drill gauges and fixtures made by the Tool Room. Extremely accurate, it came from Switzerland before the war.

Used to shape small punches and forming tools, this high speed shaper operated by William Fern makes 200 cuts a minute, can be slowed down to 14 strokes a minute when working on extremely hard steels.

THE PICTURE ON THE COVER

Our cover this month shows a few of the more than 200 different kinds and sizes of tool steel which are kept always on hand in the East Plant Tool Room. In many cases harder than diamonds, some of these special steels are worth more than $3.00 a pound. Checking over the compact $36,000 pile of steel are William Barr, who has charge of No. 18 Stores tool steel stock, and Fred Bannister.

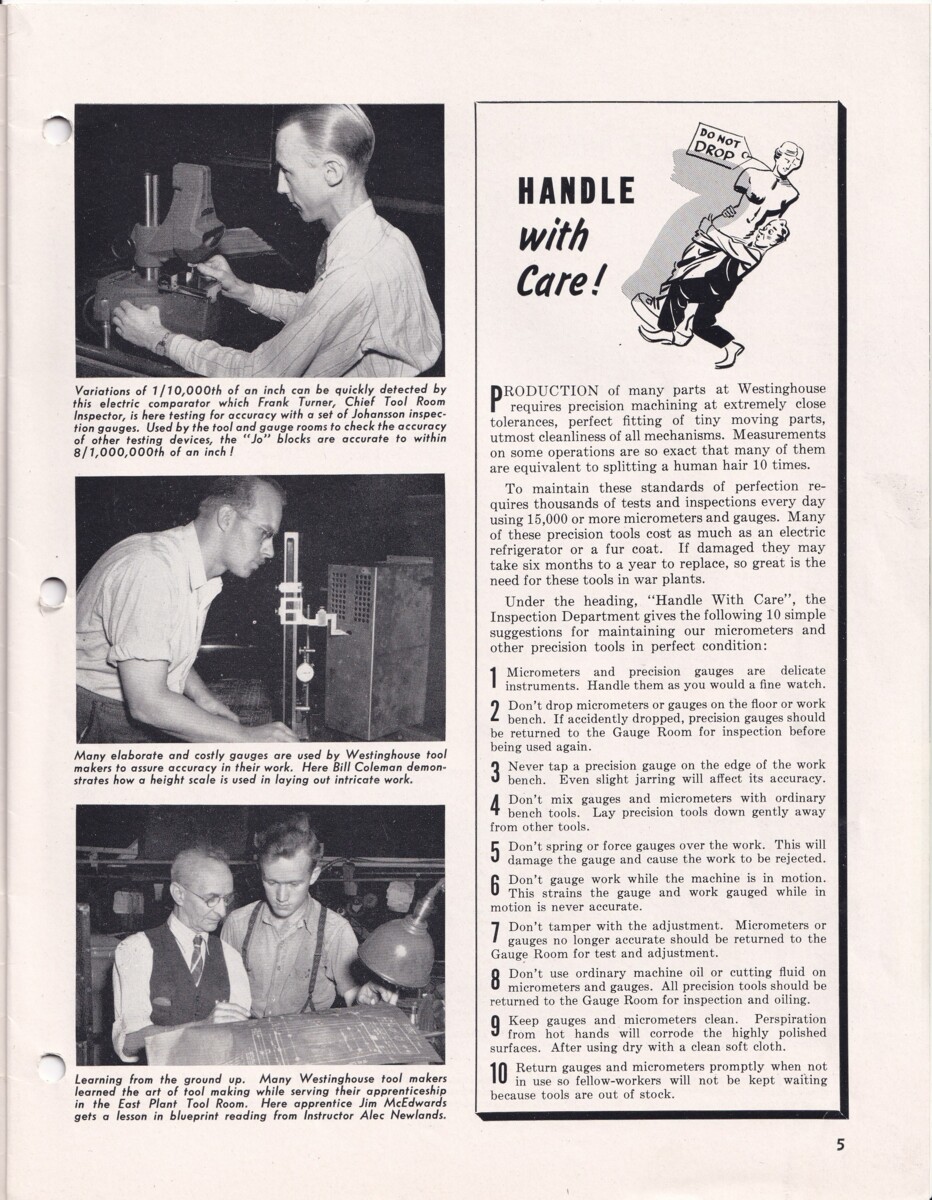

Variations of 1/10,000th of an inch can be quickly detected by this electric comparator which Frank Turner, Chief Tool Room Inspector, is here testing for accuracy with a set of Johansson inspection gauges. Used by the tool and gauge rooms to check the accuracy of other testing devices, the “Jo” blocks are accurate to within 8/1,000,000th of an inch!

Many elaborate and costly gauges are used by Westinghouse tool makers to assure accuracy in their work. Here BIll Coleman demonstrates how a height scale is used in laying out intricate work.

Learning from the ground up. Many Westinghouse tool makers learned the art of tool making while serving their apprenticeship in the East Plant Tool Room. Here apprentice Jim McEdwards gets a lesson in blueprint reading from Instructor Alec Newlands.

5

Handle with care!

Production of many parts at Westinghouse requires precision machining at extremely close tolerances, perfect fitting of tiny moving parts, utmost cleanliness of all mechanisms. Measurements on some operations are so exact that many of them are equivalent to splitting a human hair 10 times.

To maintain these standards of perfection requires thousands of tests and inspections every day using 15,000 or more micrometers and gauges. Any of these precision tools cost as much as an electric refrigerator or a fur coat. If damaged they may take six months to a year to replace, so great is the need for these tools in war plants.

Under the heading, “Handle With Care”, the INspection Department gives the following 10 simple suggestions for maintaining our micrometers and other precision tools in perfect condition:

Micrometers and precision gauges are delicate instruments. Handle the as you would a fine watch.

Don’t drop micrometers or gauges on the floor or work bench. If accidentally dropped, precision gauges should be returned to the Gauge Room for inspection before being used again.

Never tap a precision gauge on the edge of the work bench. Even slight jarring will affect its accuracy.

Don’t mix gauges and micrometers with ordinary bench tools. Lay precision tools down gently away from other tools.

Don’t spring or force gauges over the work. THis will damage the gauge and cause the work to be rejected.

Don’t gauge work while the machine is in motion. This strains the gauge and work gauged while in motion is never accurate.

Don’t tamper with the adjustment. Micrometers or gauges no longer accurate should be returned to the Gauge Room for test and adjustment.

Don’t use ordinary machine oil or cutting fluid on micrometers and gauges. All precision tools should be returned to the Gauge Room for inspection and oiling.

Keep gauges and micrometers clean. Perspiration from hot hands will corrode the highly polished surfaces. After using dry with a clean soft cloth.

Return gauges and micrometers promptly when not in use so fellow-workers will not be kept waiting because tools are out of stock.

6

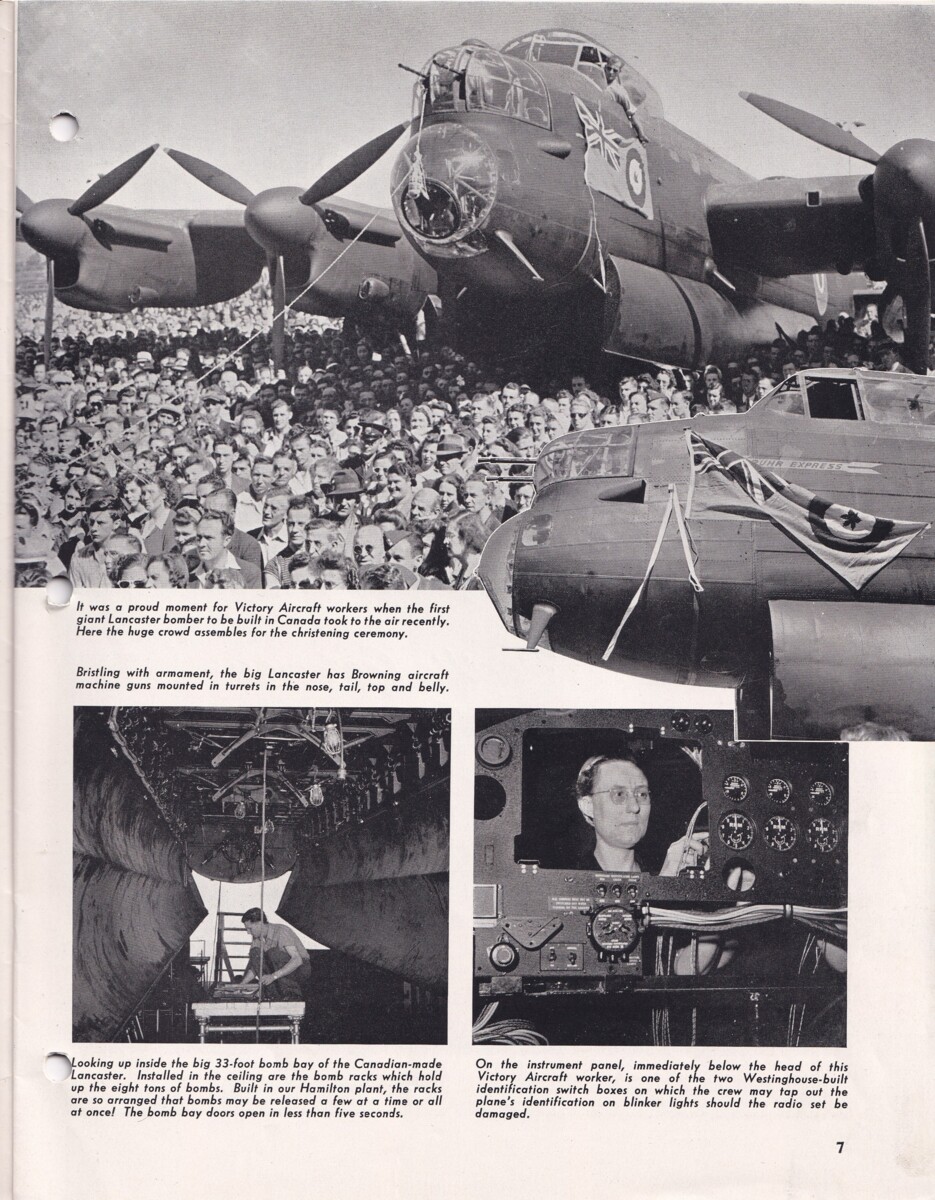

OUR LANCASTER BOMBER PARTS NOW FLY OVER GERMANY

Bomber parts made by Westinghouse war workers in Hamilton went to complete a giant Lancaster bomber last month which by now is helping to blast Germany into submission.

The first of the big Lancaster to be made in Canada, the plane was christened “The Ruhr Express” by Mrs. C. G. Power, wife of Canada’s Minister for Air, at a huge celebration at the Victory Aircraft plant at Malton early in August. Immediately after the ceremony the bomber took off for overseas.

A proud moment for Victory Aircraft workers, the honors were also shared by several of our departments at Hamilton. One of several supplier firms selected to build parts and fittings for the largest of all British heavy bombers, our plant furnished a variety of essential component parts which our years of electrical and manufacturing experience has fitted us to carry out with dispatch.

A condensed list of the equipment being produced for the Lancaster by Canadian Westinghouse includes bomb racks and bomb release mechanism, identification signal boxes, electric circuit terminal blocks, emergency aerial winch and reel, aerial insulators and ice shields, tubes for the transmitting, receiving and inter-communications sets, and flare releases. Our tool room also built special tool and assembly jigs and fixtures for use on assembly work in the Victory AIrcraft plant.

Rated the world’s largest, fastest and most devastating heavy bomber, the first Canadian Lancaster was completed, ready for action, 16 months after the arrival of blue prints from England. To produce a ship of such size in such relatively short time is a feat in itself dwarfed only by the knowledge that this was only the first of a long production line of Lancasters that will now start to roll from Canada’s largest aircraft line.

Exclusive of rivets, nuts and bolts, the Lancaster has more than 50,000 parts and assemblies, not counting the engines and gun turrets. Over 4,000 square feet of aluminum sheets are needed to cover the fuselage and wings, and approximately one million rivets and 14,250 bolts are used in the construction. The huge 69½-foot fuselage is built and assembled in sections, each section being wired and fitted before it reaches the final assembly floor. This unique assembly not only saves time in building the ships but permits sections damaged in action to be quickly replaced by boltin in new sections. THe radio, inter-communication, control and lighting circuits are likewise wired in sections for quick replacement, using hundreds of little Westinghouse-built terminal blocks.

The tremendous size of the Lancaster is apparent in the photos on these pages. From tip to tip the wings measure 102 feet. Seated at his controls the pilot is 18 feet off the ground. The wheels are fix feet six inches in diameter and are retractable. Including the eight ton bomb load, the plane weighs 30 tons. With its four motors, each developing 1,250 horsepower, it can fly 1,000 miles non-stop with a full load of bombs or 3,000 miles with a partial load.

The 69½-foot Lancaster fuselage is built and assembled in sections. The sections arrive on the final assembly floor fitted and wired ready to be joined together. Exclusive of rivets, nuts and bolt,s the plane has 50,000 different assemblies, yet is one of the best aircraft to build from a production standpoint.

The only components of the Lancaster which are not made in the Dominion are the four Rolls Royce Merlin engines which power the 30-ton ship. In flight the wheels are drawn up to increase speed.

7

It was a proud moment for Victory Aircraft workers when the first giant Lancaster bomber to bue built in Canada took to the air recently. Here the huge crowd assembles for the christening ceremony.

Bristling with armament, the big Lancaster has Browning aircraft machine guns mounted in the turrets in the nose, tail, top and belly.

Looking up inside the big 33-foot bomb bay of the Canadian-made Lancaster. Installed in the ceiling are the bomb racks which hold up the eight tons of bombs. Built in our Hamilton plant, the racks are so arranged that bombs may be released a few at a time or all at once! The bomb bay doors open in less than five seconds.

On the instrument panel, immediately below the head of this Victory Aircraft worker, is one of the two Westinghouse-built identification switch boxes on which the crew may tap out the plane’s identification blinker lights should the radio set be damaged.

8

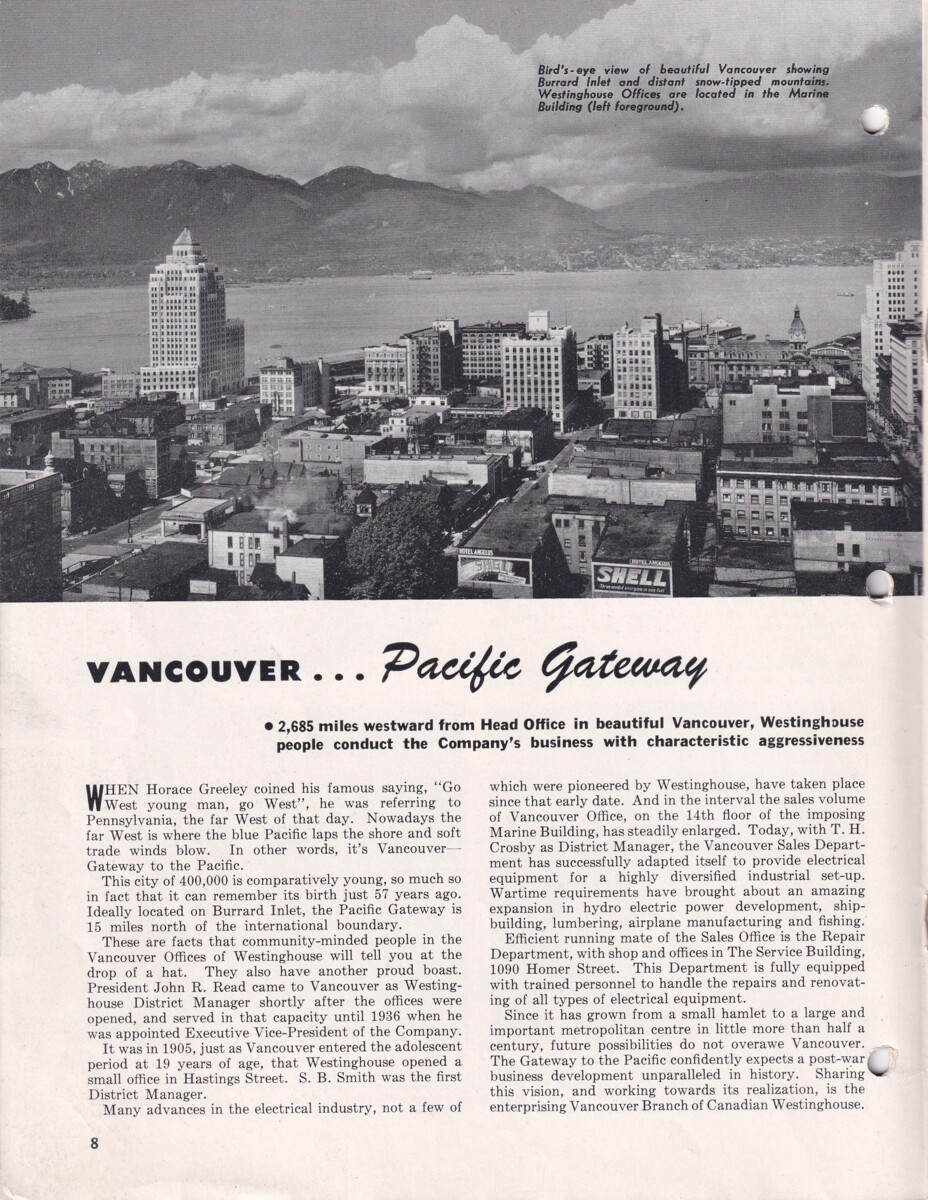

Bird’s - eye view of beautiful Vancouver showing BUrrard Inlet and distant snow-tipped mountains. Westinghouse Officers are located in the Marine Building (left foreground).

VANCOUVER … Pacific Gateway

2,685 miles westward from Head Office in beautiful Vancouver, Westinghouse people conduct the Company’s business with characteristic aggressiveness

When Horace Greeley coined his famous saying, “Go West young man, go West”, he was referring to Pennsylvania, the far West of that day. Nowadays the far West is where the blue Pacific laps the shore and soft trade winds blow. In other words, it’s Vancouver - Gateway to the Pacific.

The city of 400,000 is comparatively young, so much so in fact that it can remember its birth just 57 years ago. Ideally located on Burrard Inlet, the Pacific Gateway is 15 miles north of the international boundary.

These are facts that community-minded people in the Vancouver Offices of Westinghouse will tell you at the drop of a hat. They also have another proud boast. President John R. Read came to Vancouver as Westinghouse District Manager shortly after the offices were opened, and served in that capacity until 1936 when he was appointed Executive Vice-President of the Company.

It was in 1905, just as Vancouver entered the adolescent period at 19 years of age, that Westinghouse opened a small office in Hastings Street. S. B. Smith was the first District Manager.

Many advances in the electrical industry, not a few of which were pioneered by Westinghouse, have taken place since that early date. And in the interval the sales volume of Vancouver Office, on the 14th floor of the imposing Marine Building, has steadily enlarged. Today, with T. H. Crosby as District Manager, the Vancouver Sales Department has successfully adapted itself to provide electrical equipment for a highly diversified industrial set-up. Wartime requirements have brought about an amazing expansion in hydro electric power development, ship-building, lumbering, airplane manufacturing and fishing. Efficient running mate of the Sales Office is the Repair Department, with shop and offices inThe Service Building, 1090 Homer Street. This Department is fully equipped with trained personnel to handle the repairs and renovating of all types of electrical equipment.

Since it has grown from a small hamlet to a large and important metropolitan centre in little more than half a century, future possibilities do not overaw Vancouver. The Gateway to the Pacific confidently expects a post-war business development unparalleled in history. Sharing this vision, and working towards its realization, is the enterprising Vancouver Branch of Canadian Westinghouse.

9

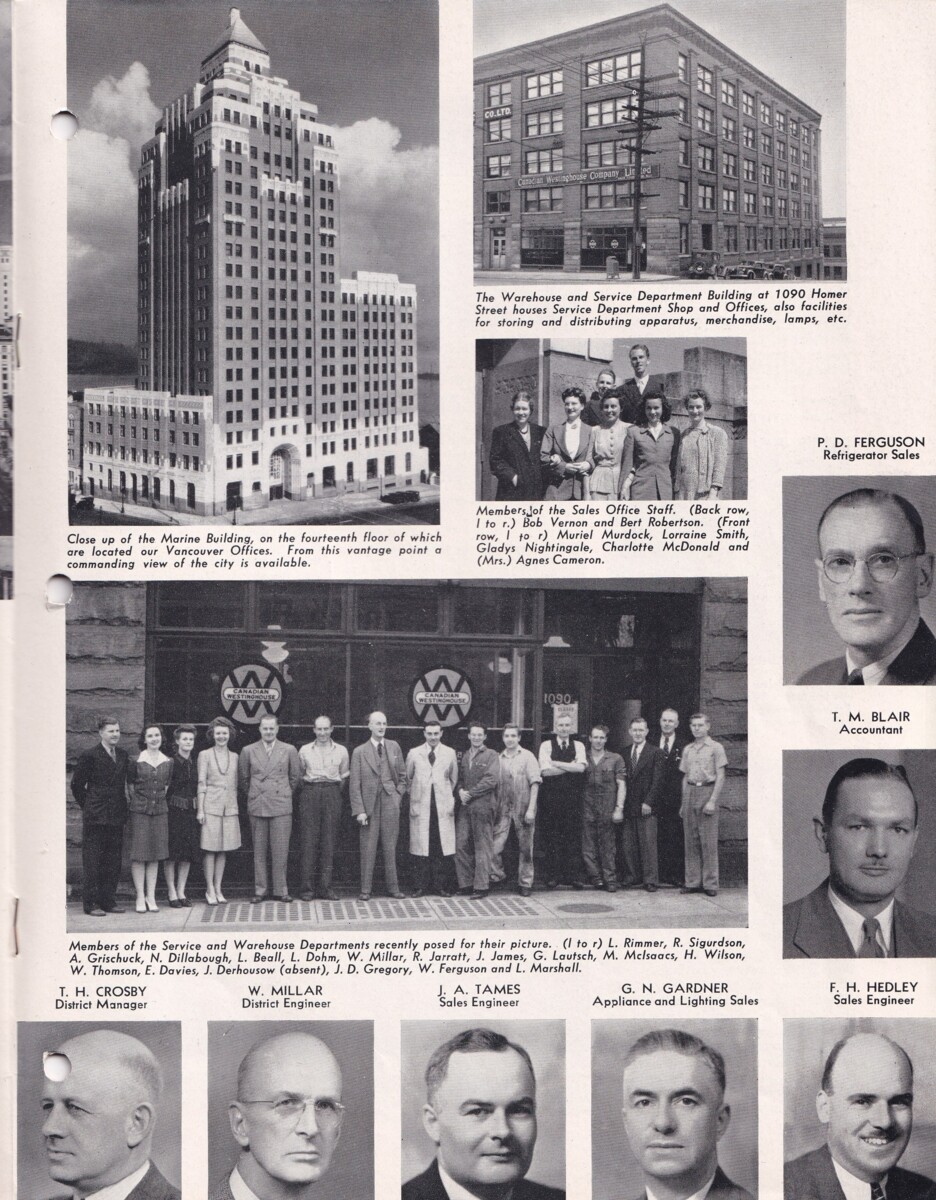

The Warehouse and Service Department Building at 1090 Homer Street houses Service Department SHop and Offices, also facilities for storing and distributing apparatus, merchandise, lamps, etc.

Close up of the Marine Building on the fourteenth floor of which are located our Vancouver Offices. From this vantage point a commanding view of the city is available.

Members of the Sales Office Staff. (Back row, l to r.) Bob Vernon and Bert Robertson. (Front row, l to r.) Muriel Murdock, Lorraine Smith, Gladys Nightingale, Charlotte McDonald and (Mrs.) Agnes Cameron.

Members of the Service and Warehouse Departments recently posed for their picture. (l to r) L. Rimmer, R. Sigurdson, A. Grischuck, N. Dillabough, L. Beal, L. Dohm, W. Millar, R. Jarratt, J. James, G. Lautsch, M. McIsaacs, H. Wilson, W. Thomson, E. Davies, J. Derhousow (absent), J.D. Gregory, W. Ferguson, and L. Marshall.

P. D. Ferguson

Refrigerator Sales

T.M. BLair

Accountant

T. H. Crosby

District Manager

W. Millar

District Engineer

J.A. Tames

Sales Engineer

G.N. Gardner

Appliance and Lighting Sales

F.H. Hedley

Sales Engineer

10

NEWS IN REVIEW

EAST PLANT

General Office- The Service Department had the pleasure of a visit from Tom Eastwood, Foreman of our Service Repair Shop at Winnipeg. Tom was on his way to attend the presentation of Wings to his son, Glenn, formerly one of our employees, at Uplands, on August 6th. Glenn was an apprentice at Hamilton before joining up in March of last year.

Engineering- Joe Thwaites was recently made a member of the Electronics Committee, American Institute of Electrical Engineers. Joe is the only Canadian on the Committee and is to be congratulated on his appointment.

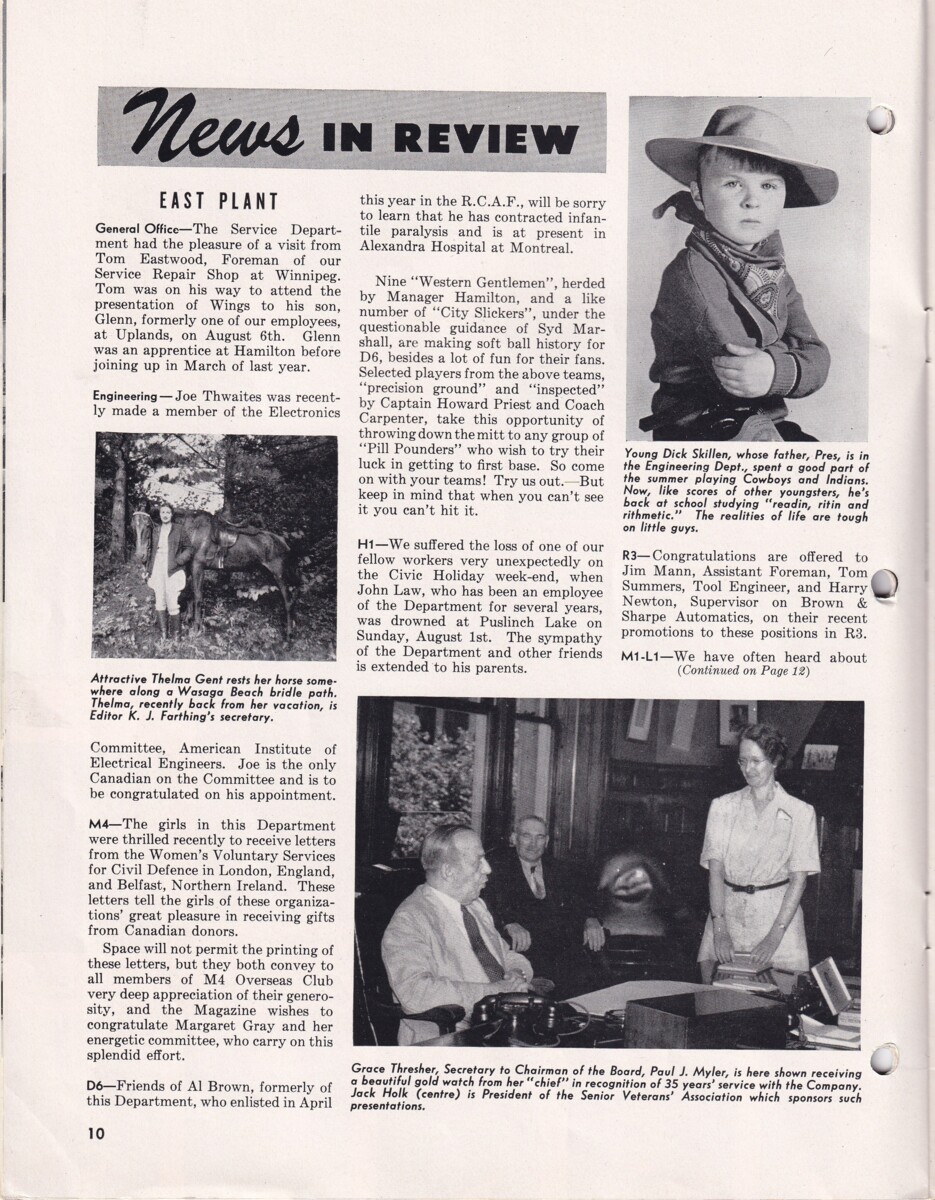

Attractive Thelma Gent rests her horse somewhere along a Wasaga Beach bridle path. THelma, recently back from her vacation, is Editor K.J. Farthing’s secretary.

M4- The girls in this Department were thrilled recently to receive letters from the Women’s Voluntary Services for Civil Defence in London, England, and Belfast, Northern Ireland. THese letters tell the girls of these organizations’ great pleasure in receiving gifts from Canadian donors.

Space will not permit the printing of these letters, but they both convey to all members of M4 Overseas Club very deep appreciation of their generosity, and the Magazine wishes to congratulate Margaret Gray and her energetic committee, who carry on this splendid effort.

D6- Friends of Al Brown, formerly of this Department, who enlisted in April this year in the R.C.A.F., will be sorry to learn that he has contracted infantile paralysis and is at present in Alexandra Hospital at Montreal.

Nine “Western Gentlemen”, herded by Manager Hamilton, and a like number of “City Slickers”, under questionable guidance of Syd Marshall, are making soft ball history for D6, besides a lot of fun for their fans. Selected players from the above teams, “precision ground” and “inspected” by Captain Howard Priest and Coach Carpenter, take this opportunity of throwing down the mitt to any group of “Pill Pounders” who wish to try their luck in getting to first base. So come on with your teams! Try us out.-But keep in mind that when you can’t see it you can’t hit it.

H1-We suffered the loss of one of our fellow workers very unexpectedly on the Civic Holiday week-end, when John Law, who has been an employee of the Department for several years, was drowned at Puslinch Lake on Sunday, August 1st. The sympathy of the Department and other friends is extended to his parents.

Grace Thresher, Secretary to Chairman of the Board, Paul J. Myler, is here shown receiving a beautiful gold watch from her “chief” in recognition of 35 years’ service with the Company. Jack Holk (centre) is PResident of the Senior Veterans’ Association which sponsors such presentations.

Young Dick Skillen, whose father, Pres, is in the Engineering Dept., spent a good part of the summer playing Cowboys and Indians. Now, like scores of other youngsters, he’s back at school studying “readin, ritin, and arithmetic.” The realities of life are tough on little guys.

R3- Congratulations are offered to Jim Mann, Assistant Foreman, Tom Summers, Tool Engineer, and Harry Newton, Supervisor on Brown & Sharpe Automatics, on their recent promotions to these positions in R3.

M1-L1-We have often heard about (Continued on Page 12)

11

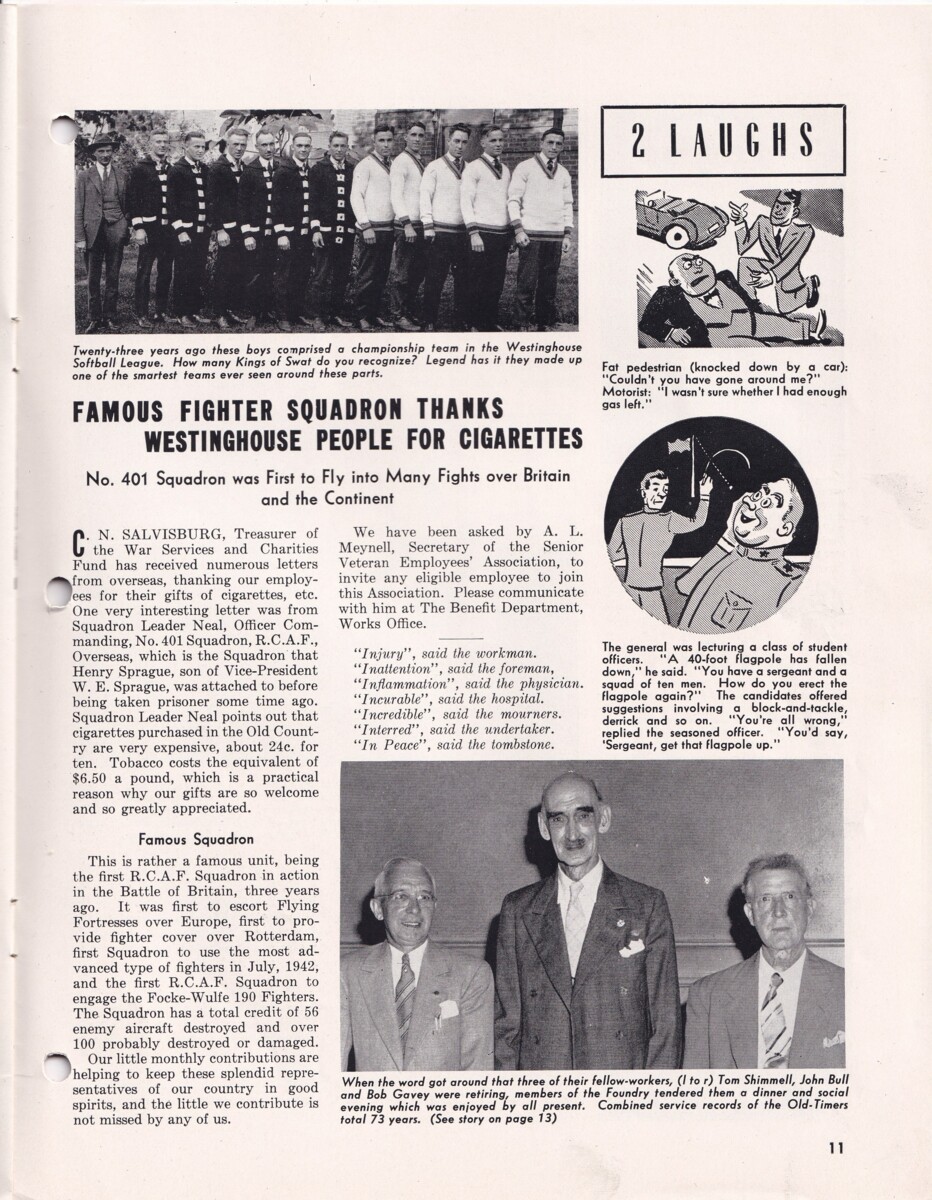

Twenty-three years ago these boys comprised a championship team in the Westinghouse Softball League. How many Kings of Swat do you recognize? Legend has it they made up one of the smartest teams ever seen around these parts.

2 LAUGHS

Fat pedestrian (knocked down by a car):

“Couldn’t you have gone around me?”

Motorist: “I wasn’t sure whether I had enough gas left.”

The general was lecturing a class of student officers. “A 40-foot flagpole has fallen down,” he said. “You have a sergeant and a squad of ten men. How do you erect the flagpole again?” The candidates offered suggestions involving a block-and-tackle, derrick and so on. “You’re all wrong,” replied the seasoned officer. “You’d say, ‘Sergeant, get that flagpole up.”

FAMOUS FIGHTER SQUADRON THANKS WESTINGHOUSE PEOPLE FOR CIGARETTES

No. 401 Squadron was First to Fly in Many Fights over Britain and the Continent.

C.N. SALVISBURG, Treasurer of the War Services and Charities Fund has received numerous letters from overseas, thanking our employees for their gifts of cigarettes, etc. One very interesting letter was from Squadron Leader Neal, Officer Commanding, No. 401 Squadron, R.C.A.F., Overseas, which is the Squadron that Henry Sprague, son of VIce-President W.E. Sprague was attached to before being taken prisoner some time ago. Squadron Leader Neal points out that cigarettes purchased in the Old Country are very expensive, about 24c. For ten. Tobacco costs the equivalent of $6.50 a pound, which is a practical reason why our gifts are so welcome and so greatly appreciated.

Famous Squadron

This is rather a famous unit, being the first R.C.A.F. Squadron in action in the Battle of Britain, three years ago. It was first to escort Flying FOrtresses over Europe, first to provide fighter cover over Rotterdam, first Squadron to use the most advanced type of fighters in July, 1942, and the first R.C.A.F. Squadron to engage the Focke-Wulfe 190 Fighters. The Squadron has a total credit of 56 enemy aircraft destroyed and over 100 probably destroyed or damaged.

Our little monthly contributions are helping to keep these splendid representatives of our country in good spirits, and the little we contribute is not missed by any of us.

We have been asked by A.L. Meynell, Secretary of the Senior Veteran Employees’ Association, to invite any eligible employee to join this Association. Please communicate with him at The Benefit Department, Works Office.

“Injury”, said the workman.

“Inattention”, said the foreman,

“Inflammation”, said the physician.

“Incurable”, said the hospital.

“Incredible”, said the mourners.

“Interred”, said the undertaker.

“In Peace”, said the tombstone.

When the word got around that three of their fellow-workers, (l to r) Tom Shimmell, John Bull and Bob Gavey were retiring, members of the Foundry tendered them a dinner and social evening which was enjoyed by all present. Combined service records of the Old-Timers total 73 years. (See story on page 13)

12

…the big one that got away, but Russ Bea (M1) not only let the big one get away, but his line, rod, reel and a two dollar spinner went with it. We are all wondering how Russ is going to explain the loss to his brother-in-law, the late owner of the aforementioned equipment.

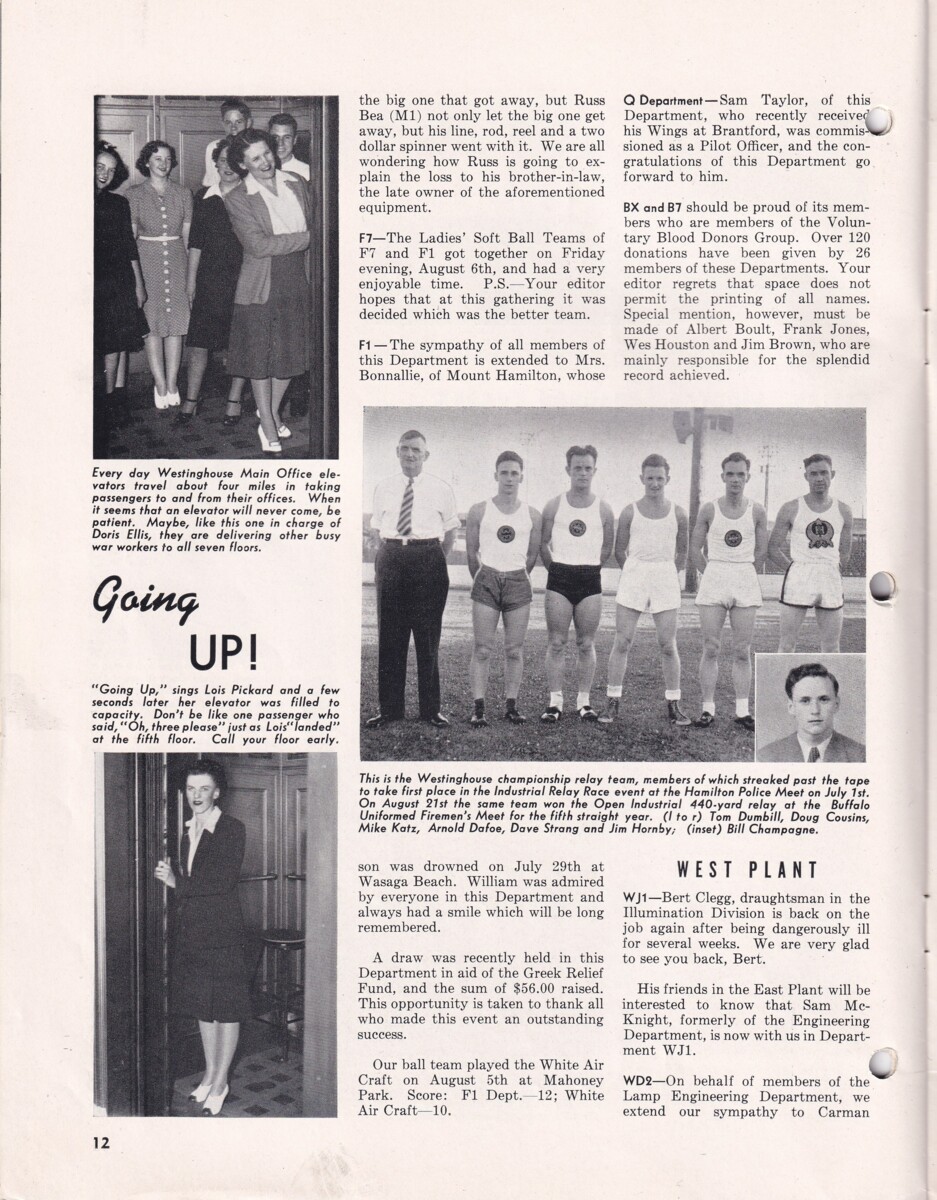

Every day Westinghouse Main Office elevators travel about four miles in taking passengers to and from their offices. When it seems that an elevator will never come, be patient. Maybe, like this one in charge of Doris Ellis, they are delivering other busy war workers to all seven floors.

Going UP!

“Going Up,'' sings Lois Pickard and a few seconds later her elevator was filled to capacity. Don’t be like one passenger who said “Oh, three please” just as Lois “landed” at the fifth floor. Call your floor early.

F-7-The Ladies’ Soft Ball Teams of F7 and F` got together on Friday evening, August 6th and had a very enjoyable time. P.S.-Your editor hopes that at his gathering it was decided which was the better team.

This is the Westinghouse championship relay team, members of which streaked past the tape to take first place in the Industrial Relay Race event at the Hamilton Police Meet on July 1st. On August 21st the same team won the Open Industrial 440-yard relay at the Buffalo Uniformed Firemen’s Meet for the fifth straight year. (l to r) Tom Dumbill, Doug Cousins, Mike Katz, Arnold Dafoe, Dave Strang and Jim Honrsby; (inset) Bill Champagne.

F1-The sympathy of all members of this Department is extended to Mrs. Bonnallie, of Mount Hamilton, whose son was drowned on July 29th at Wasaga Beach. William was admired by everyone in this Department and always had a smile which will be long remembered.

A draw was recently held in this Department in aid of the Greek Relief Fund, and the sum of $56.00 raised. This opportunity is taken to thank all who made this event an outstanding success.

Our ball team played the White Air Craft on August 5th at Mahoney Park: Score: F1 Dept.-12; White Air Craft-10.

Q Department- Sam Taylor, of this Department, who recently received his Wings at Brantford, was commissioned as a Pilot Officer, and the congratulations of this Department go forward to him.

BX and B7 should be proud of its members who are members of the Voluntary Blood Donors Group. Over 120 donations have been given by 26 members of these Departments. Your editor regrets that space does not permit the printing of all names. Special mention, however, must be made of Albert Boult, Frank Jones, Wes Houston and Jim Brown, who are mainly responsible for the splendid record achieved.

WEST PLANT

WJ1-Berg Clegg, draughtsman in the Illumination Division is back on the job again after being dangerously ill for several weeks. We are very glad to see you back, Bert.

His friends in the East PLant will be interested to know that Sam McKNight, formerly of the Engineering Department, is now with us in Department WJ1.

WD2-On behalf of members of the Lamp Engineering Department, we extend our sympathy to Carman Cantlon, whose mother passed away recently at Seaforth. Also to James Radcliffe, Pipe Fitter (WD2) who lost his wife on July 31st.

13

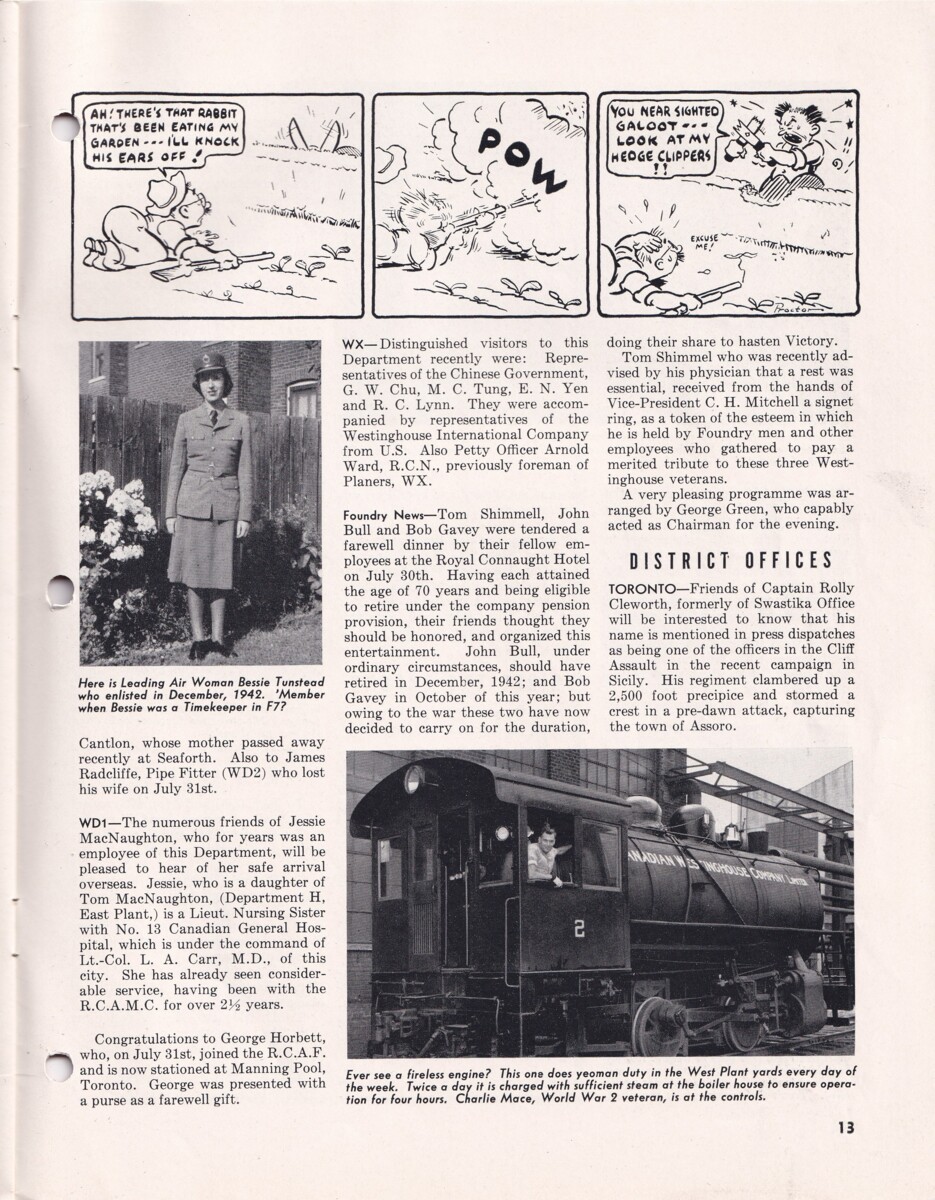

Here is LEading Air Woman Bessie Tunstead who enlisted in December, 1942. ‘Member when Bessie was a Timekeeper in F7?

WD1-The numerous friends of Jessie MacNaughton, who for years was an employee of this Department, will be pleased to hear of her safe arrival overseas. Jessie, who is a daughter of Tom MacNaughton, (Department H, East Plant,) is a Lieut. Nursing Sister with No. 13 Canadian General Hospital, which is under the command of Lt.-Col. L.A. Carr, M.D., of this city. She has already seen considerable service, having been with the R.C.A.M.C. for over 2½ years.

Congratulations to Geroge Horbett, who, on July 31st, joined the R.C.A.F. and is now stationed at Manning Pool, Toronto. George was presented with a purse as a farewell gift.

WX-Distinguished visitors to this Department recently were: Representatives of the Chinese Government, G.W. Chu, M.C. Tung, E.N. Yen and R.C. Lynn. They were accompanied by representatives of the Westinghouse International Company from U.S. Also Petty Officer Arnold War, R.C.N., previously foreman of Planers, WX.

Foundry News- Tom Shimmell, John Bull and Bov Gavey were tendered a farewell dinner by their fellow employees at the Royal Connaught Hotel on July 30th. Having each attained the age of 70 years and being eligible to retire under the company pension provision, their friends thought they should be honored, and organized this entertainment. John Bull, under ordinary circumstances, should have retired in December, 1942; and Bob Gavey in October of this year; but owing to the war these two have now decided to carry on for the duration doing their share to hasten Victory. Tom Shimmell who was recently advised by his physician that a rest was essential, received from the hands of Vice-President C.H. Mitchell a signet ring, as a token of the esteem in which he is held by Foundry men and other employees who gathered to pay a merited tribute to these three Westinghouse veterans. A very pleasing program was arranged by George Green, who capably acted as Chairman for the evening.

DISTRICT OFFICES

TORONTO- Friends of Captain Rolly Cleworth, formerly of Swastika Office will be interested to know that his name is mentioned in press dispatches as being one of the officers in the Cliff Assault in a recent campaign in Sicily. His regiment clambered up a 2,500 foot precipice and stormed a crest in a pre-dawn attack, capturing the town of Assoro.

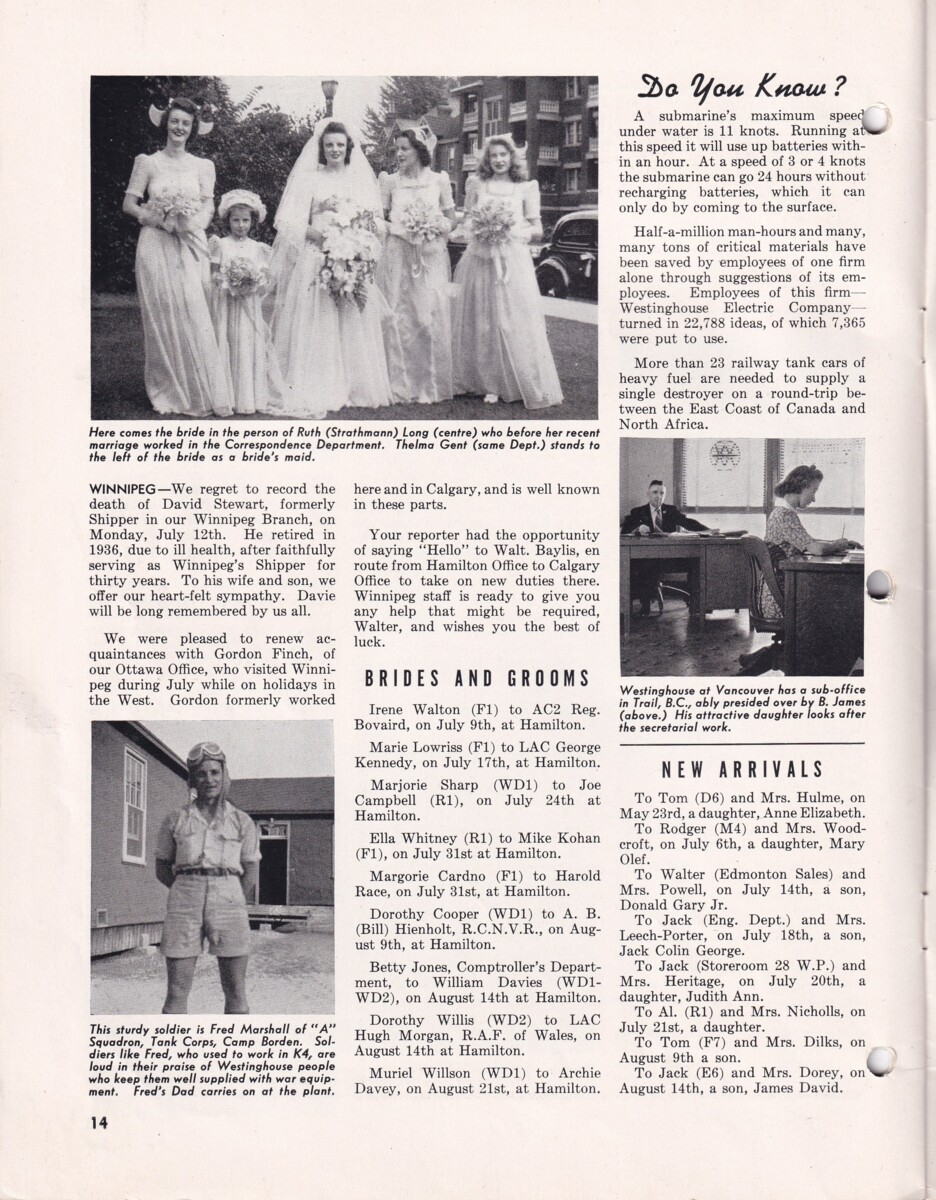

Ever see a fireless engine? This one does yeoman duty in the West Plant yards every day of the week .Twice a day it is charged with sufficient steam at the boiler house to ensure operation for four hours. Charlie Mace, World War 2 veteran is at the controls.

14

Here comes the bride in the person of Ruth (Strathmann) Long (centre) who before her recent marriage worked in the Correspondence Department. THelma Gent (same Dept.) stands to the left of the bride as a bride’s maid.

WINNIPEG- We regret to record the death of David Stewart, formerly Shipper in our Winnipeg Branch, on Monday, July 12th. He retired in 1936, due to ill health, after faithfully serving as Winnipeg’s Shipper for thirty years. To his wife and son, we offer our heart-felt sympathy. Davie will be long remembered by us all.

We are pleased to renew acquaintances with Gorgon Finch, of our Ottawa Office, who visited Winnipeg during July while on holidays in the West. Gordon formerly worked here and in Calgary, and is well known in these parts.

Your reporter had the opportunity of saying “Hello” to Walt. Baylis, en route from Hamilton Office to Calgary Office to take on new duties there. Winnipeg staff is ready to give you any help that might be required, Walter, and wishes you the best of luck.

This sturdy soldier is Fred Marshall of “A” Squadron, Tank Corps, Camp Borden. Soldiers like Fred, who used to work in K4, are loud in their praise of Westinghouse people who keep them well supplied with war equipment. Fred’s Dad carries on that at the plant.

BRIDES AND GROOMS

Irene Walton (F1) to AC2 Reg. Bovaird, on July 9th, at Hamilton.

Marie Lowriss (F1) to LAC George Kennedy, on July 17th at Hamilton.

Marjorie Sharp (WD1) to Joe Campbell (R1), on July 24th at Hamilton.

Ella WHitney (R1) to Mike Kohan (F1), on July 31st at Hamilton.

Margorie Cardno (F1) to Harold Race, on July 31st, at Hamilton.

Dorothy Cooper (WD1) to A.B. (Bill) Heinhold, R.C.N.V.R., on August 9th at Hamilton.

Betty Jones, Comptroller’s Department, to William Davies (WD1-WD2), on August 14th at Hamilton.

Dorothy WIllis (WD2) to LAC Hugh Morgan, R.A.F. of Wales, on August 14th at Hamilton.

Muriel Willson (WD1) to Archie Davey, on August 21st at Hamilton.

Do you know?

A submarine’s maximum speed under water is 11 knots. Running at this speed it will use up batteries in an hour. At a speed of 3 or 4 knots the submarine can go 24 hours without recharging batteries, which it can only do by coming to the surface.

Half-a-million man-hours and many, many tons of critical materials have been saved by employees of one firm alone through suggestions of its employees. Employees of this firm-Westinghouse Electric Company- turned 22,788 ideas, of which 7,365 were put to use.

More than 23 railway tank cars of heavy fuel are needed to supply a single destroyer on a round-trip between the East Coast of Canada and North Africa.

Westinghouse at Vancouver has a sub-office in Trail, B.C. ably presided over by B. James (above) His attractive daughter looks after the secretarial work.

NEW ARRIVALS

To Tom (D6) and Mrs. Hulme, on May 23rd, a daughter, Anne Elizabeth.

To Rodger (M4) and Mrs. Woodcroft, on July 6th, a daughter, Mary Olef.

To Walter (Edmonton Sales) and Mrs. Powell, on July 14th, a son, Donald Gary Jr.

To Jack (Eng. Dept.) and Mrs. Leech-Porter, on July 18th, a son, Jack Colin George.

To Jack (Storeroom 28 W.P.) and Mrs. Heritage, on July 20th, a daughter, Judith Ann.

To A1. (R1) and Mrs. Nicholls, on July 31st, a daughter.

To Tom (F7) and Mrs. Dilks, on August 9th a son.

To Jack (E6) and Mrs. Dorey, on August 14th, a son, James David.

15

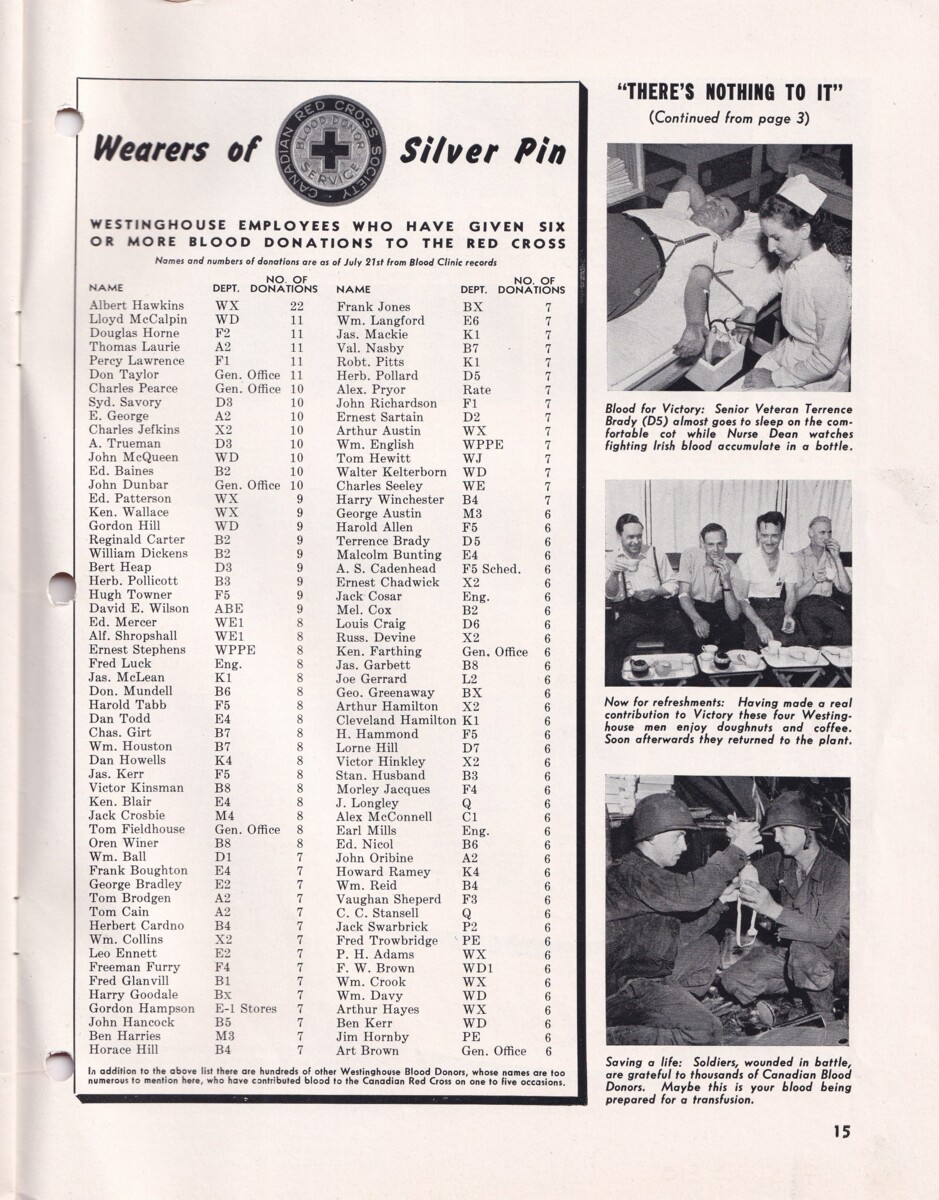

Wearers of Canadian Red Cross Society Silver Pin

Westinghouse Employees who have given Six or more Blood Donations to the Red Cross

“THERE’S NOTHING TO IT”

(Continued from page 3)

Blood for Victory: Senior Veteran Terrence Brady (D5) almost goes to sleep on the comfortable cot while Nurse Dean watches fighting Irish blood accumulate in a bottle.

Now for refreshments: Having made a real contribution to Victory these four Westinghouse men enjoy doughnuts and coffee. Soon afterwards they returned to the plant.

Saving a life: Soldiers, wounded in battle, are grateful to thousands of Canadian Blood Donors. Maybe this is your blood being prepared for a transfusion.

Back cover

Kenneth Holden Sergeant R.C.A.F. After working four years in our Vancouver Office, Kenneth enlisted in 1941. Since that time he has often flown over enemy land.

Robert Henry Pte. R.H.L.I. Bob worked two years in the Shipping Dept. Enlisted before the war was a month old. His wife and little brother, Sharon, remain here.

William Dohm Able Seaman, R.C.N.V.R. was in the Vancouver Office 5 years before joining the Navy in 1940. He likes the life but will be glad to return to his former job.

J.A. Turner Leading Air Craftsman, R.C.A.F. Joe was a well-liked member of the Winnipeg Service Dept. before joining the air force three years ago this Sept.

James Walker R.Q.M., Fifth Field Ambulance, R.C.A.M.C. “Mickey” was in X2 Deparmtnet for 17 years. He joined up in 1939. His father is in R.I. Dept.

Milton Edwards, Flying Officer, R.C.A.F. Milt. enlisted in July, 1942, after working for five years in our Hamilton and Vancouver Offices where he has many old friends.

Donald McLeod F/O R.C.A.F. First Rate Dept. man to enlist. He was commissioned overseas in 1942, and taken prisoner in action against the German fleet.

Owen Boylan Lance Corporal, R.C.O.C., Fifth Canadian Division Overseas. Owen worked for more than a year in P-2 Department before going active in 1941.

John McGurrin Corporal, R.C.A.S.C., Canadian Army Overseas. John was a member of the Carpenter Shop for twelve years prior to donning the uniform in 1940.

J. Tuckett Steward, H.M.C.S. Protector No. 2, Point Edward Base, Sydney, N.S. He joined the Canadian Navy in May, 1942 after working one year in WD-1.

Roy Spree Able Seaman, R.C.N.V.R. Roy decided in favour of His Majesty’s Navy in October 1941. Was previously employed for six months in the Lamp Dept.

Ernie Goodwin Sgt. R.C.A.F. Overseas. He donned a uniform in April 1942 and before that worked for a year in FI and CI Dept. His wife, Lorraine, works in FI Dept.

Jack Arnold Sgt. 40th Battery, Canadian Army Overseas. Worked in Dept. B-4 eleven years. Joined the colours day war declared. A brother Frank, in K-1 Dept.

A. Normally Ships Writer, Royal Canadian Naval Volunteer Reserve. Before deciding to cast his lot with the Navy, Austin worked in the Stores Department 6 months.

Fred Kneebone, Jr. Stoker 1st Class, R.C.N.V.R. Fred was in A-2 Dept. as a welder for three years. He enlisted in April 1943. His father, Fred Sr., works in A-2 Dept.

Gordon Bone Flight Sergeant R.C.A.F. Gord enlisted from the Stores Office in January 1941. He is now attached to the Royal Canadian Air Force in Cairo, Egypt.

William Lawson Pte., Royal Regiment of Canada, Canadian Army Overseas. Bill worked for one year in the Stores Office before enlisting in July 1942. Likes the Army.

L. Baldasero Trooper, British Columbia Dragoons. Lorne, who worked for 2 years in E-6 Department, joined up in March 1942. Writes Home Front Friends.

D. Caldbeck Leading Air Craftsman R.C.A.F. Was well-known in Vancouver Branch where he worked for nine years. Don enlisted in May, 1943 and was soon overseas.

Joseph Prior Leading Air Craftsman, R.C.A.F. Joe was a valued member of the Stores Office for two years before going active in July 1941. He is now in Ceylon.

Joe Clayton P.O., E.R.A., R.C.N.V.R. Joined Company six years ago and upon enlistment in April, 1943, was a Sheet Metal Worker in A-2. His brother in B-4.

Frank May Flying Officer, R.C.A.F. Frank was with the Company for four years as an Inspector in E-I Shipping and Receiving Department. He enlisted in April 1941.

Art Blackwell Pte., Royal Canadian Ordnance Corps, Canadian Army Overseas. Art was well-known in Hamilton and Vancouver Office, where he worked for 17 years.

Comrades in Arms

*Only difference between these lads and us is that they fight dangerously overseas while we carry on Freedom’s battle safe in a Westinghouse War Plant. It’s like rugby - We pass the ball, they make the touchdown. The more war materials made here, the easier it becomes for our boys to score against the enemy.

Perhaps you have photos of Westinghouse men overseas. Please send them to Editor K. J. Farthing, Room 415, General Office. Such pictures are urgently needed in order to continue this back page feature.

2

Wherever super cleanliness is vital to health - in hospitals, restaurants, food industries, etc., the Westinghouse Sterilamp is doing a man-size job. Its rays spell doom for germs. In our cafeteria (above) a Sterilamp constantly stands guard over the cutlery.

THE DEATH RAY THAT GUARDS LIFE

Westinghouse is fighting two wars at once. Everyone knows about the many types of weapons manufactured here for effective use against the Nazis. But few are aware that fixtures and bulbs for the Sterilamp, which protects health by killing germs, are made in the West End Plant.

The Sterilamp wars against bacteria on many fronts. By producing strong ultra-violet rays it does its biggest health job in hospitals. Infections which formerly occurred after major operations are now controllable through installation of these wonder lamps over operating tables. Sanitary conditions are similarly maintained in food industries, laboratories engaged in the preparation of essential vaccines, restaurants, meat stores, etc.

In appearance, the Westinghouse Sterilamp is a slender rod-shaped glass tube, flaring slightly at each end where the electrodes are located. Sterilamps operate on alternating current through the medium of current regulating transformers.

Although installations are restricted for the duration to essential industries and services, many new uses for the Sterilamp are anticipated in post-war years. A device that guards public health by killing germs in the millions deserves a bright future.

INFLATION WILL GET US IF WE DON’T WATCH OUT

Those of us who remember the last war have vivid recollections of how high the prices of common things soared. In Hamilton, for instance, butter sold for 65c, a pound, sugar for 29c potatoes for $1.22 a ten-pound bag, and work boots, which were very often of only imitation leather, were $12.00 a pair. In fact, in those days, we paid nearly twice as much as we are paying for the same articles today, and to add to the difficulties, there was a shortage of practically everything, which, in turn, resulted in higher prices being demanded.

You see, people were making very high wages- more money in fact than they could spend in wartime- and with the surplus money they were continually striving to outbid each other for the scarce goods. This forced the prices up, which necessitated an increase in wages. Thus, alternately, prices and wages went higher and higher, with the wages never quite catching up- always coming out second best. The Government in that day took no effective steps to prevent this trend.

That is inflation. True, it wasn’t called by that name in the last war, but it has occured- to a great or less degree- during every war period.

Of course, all of us would like to have more money. Actually what we want is to be able to purchase more goods- to improve our standard of living. Under conditions of inflation, however, getting more money does not improve the standard of living, since an increase in wages results in an increase in the price of goods which is greater in proportion than the wage increase. Thus, the standard of living is actually lowered.

This is what happened in the last war and is what the Government is now trying to prevent by rationing scarce goods, putting a ceiling price on necessary goods, stabilizing wages, providing a Cost-of-Living Bonus, and increasing taxes.

But the Government cannot accomplish this great task alone. It takes the co-operation of every individual to make it an actual success. The Government can’t prevent inflation unless you- and you- and I are willing to undertake to carry out those things which are necessary to prevent it.

THe first requirement is to purchase only those things which we need. It is true that the temptation is great to purchase those things which we have wanted - but not actually needed- for a long time, especially when we have a bit of extra money in hand. If we confine our purchases to our needs, there will be enough of everything to go around.

Secondly, if we refuse to pay more than a fair price for what we buy, and ask only a fair price for what we have to sell- be it goods or labour- prices are bound to stay where they are at present.

Then with our surplus money, there are the old debts and mortgages to be paid off, life insurance to buy, bank accounts to be increased and Victory Bonds to purchase, and when the war is over, the slate will be clean- no bad debts, no things that have to be settled. However, there will be a “nest egg” of considerable size that we will be free to spend on long-desired luxuries, to make a down payment on a new home, or to give our boys and girls an education. All industry, freed from war production, can thus be concentrated on providing goods for the civilian population, and give full employment to thousands to supply the demand for those articles which we have done without in wartime.

We shall then have paid for the war as we went along, kept all fronts supplied with necessities, and ensured stability of our currency by preventing inflation.

John R Reed

President

3

Westinghouse Employees Magazine

Vol. 1, No. 7 September, 1943

“THERE’S NOTHING TO IT”

…say Westinghouse Employees who regularly contribute their blood to the Red Cross Blood Bank.

Just one of the gang, Albert Hawkins (WX Department) has donated blood to the Red Cross 22 times! “Nothing to it”, he says.

What would you do if your next door neighbour suddenly took ill and needed a blood transfusion? “Why,” you say, “I’d go right to the hospital and offer to give my blood.”

Now your next door neighbour’s son may be in the Armed Forces. He may be wounded and in need of a blood transfusion this very minute. Of course you can’t rush to his aid overseas as you would to his Dad who lives next door.

But like 1,000 fellow Westinghouse workers you can become a Blood Donor and thus make sure that no Canadian soldier will ever die for want of a blood transfusion.

Being a Blood Donor is easy. There’s absolutely nothing to it. Look at the pictures on this page for definite proof. We’ll just say this: There are 10,000 Blood donors in Wentworth County. Of this number one-tenth are Westinghouse people who have been organized in a great humanitarian cause mostly through the efforts of B. B. Hodge, Personnel Manager.

Let’s keep up the good work. See your Foreman today about becoming a Blood Donor. Your blood may save a Canadian soldier’s life. (Continued on page 15)

Off we go. Pretty Red Cross driver, Margaret Ambrose is about to whisk these smiling chaps off to the Blood clinic. Shown are Blood DOnors George Worthingham (No. 2 Store Room), Joe De FOrest (BX), Joe Harrison (B6), Dave McKay (A2), Terrence Brady (D5) and George Greenaway (BX).

“Your name please?” asks Miss Margaret Templin and the Westinghouse Blood Donor answers “Dave McKay, A2”. Other donors wait to register.

Temperature taking: The nurse places a thermometer in each man’s mouth. Regular Donors, they relax knowing that there’s nothing to it.

“No change in health?” asks Dr. Crack as Joe De Forest (BX) takes a Hemoglobin Test and Mrs. Radcliffe checks the record. WHat happens next is shown on page 15.

4

Our Years of Tool Making Experience has Proved Invaluable in the Switchover of Production from Peace to War.

TOOLS

FOR THE TOOLS OF WAR…

Proud of their craftsmanship are Tool Room men like Bill Sawbridge, left, and Bill Hay who do the assembly and finishing operations on the hundreds of jigs and fixtures turned out by the Tool Room every year. Working against time, the Tool Room worked seven days a week for the first two years of the war.

In mass production one of the most important groups of men in a plant like ours are the tool makers. These are the men who design and build the jigs, fixtures, dies and gauges that make possible the mass production of millions of parts and hundreds of pieces of finished equipment with accuracy.

To many in the East Plant Tool ROom this is the second time that the Tool Room has put aside the products of peace to build the tools for the tools of war.

Although Westinghouse tool makers are aided in their work by the most modern machines money can buy, tool making requires a high degree of craftsmanship. Information contained in the engineer’s blueprints must be carefully transferred to metal and the metal in turn accurately machined and finished to the required shape. Whereas machinists in other departments may work to tolerances of thousands of an inch, tool makers think in terms of hundred thousandths!

Just as jigs and fixtures require time to build, the art of tool making cannot be learned in a hurry. Many Westinghouse Tool makers, like East Plant Tool Room Foreman Ernie Porthouse, served their apprenticeship in the Tool Room. Apprentices spend four years at the bench under the guidance of an experienced tool maker as well as attending classes during the daytime and one evening a week. In spite of the exacting apprenticeship there are always many boys eagerly awaiting the opportunity to take up this course.

One of the most accurate machines of its kind is this jig borer operated by Tom MacAulay is used to drill gauges and fixtures made by the Tool Room. Extremely accurate, it came from Switzerland before the war.

Used to shape small punches and forming tools, this high speed shaper operated by William Fern makes 200 cuts a minute, can be slowed down to 14 strokes a minute when working on extremely hard steels.

THE PICTURE ON THE COVER

Our cover this month shows a few of the more than 200 different kinds and sizes of tool steel which are kept always on hand in the East Plant Tool Room. In many cases harder than diamonds, some of these special steels are worth more than $3.00 a pound. Checking over the compact $36,000 pile of steel are William Barr, who has charge of No. 18 Stores tool steel stock, and Fred Bannister.

Variations of 1/10,000th of an inch can be quickly detected by this electric comparator which Frank Turner, Chief Tool Room Inspector, is here testing for accuracy with a set of Johansson inspection gauges. Used by the tool and gauge rooms to check the accuracy of other testing devices, the “Jo” blocks are accurate to within 8/1,000,000th of an inch!

Many elaborate and costly gauges are used by Westinghouse tool makers to assure accuracy in their work. Here BIll Coleman demonstrates how a height scale is used in laying out intricate work.

Learning from the ground up. Many Westinghouse tool makers learned the art of tool making while serving their apprenticeship in the East Plant Tool Room. Here apprentice Jim McEdwards gets a lesson in blueprint reading from Instructor Alec Newlands.

5

Handle with care!

Production of many parts at Westinghouse requires precision machining at extremely close tolerances, perfect fitting of tiny moving parts, utmost cleanliness of all mechanisms. Measurements on some operations are so exact that many of them are equivalent to splitting a human hair 10 times.

To maintain these standards of perfection requires thousands of tests and inspections every day using 15,000 or more micrometers and gauges. Any of these precision tools cost as much as an electric refrigerator or a fur coat. If damaged they may take six months to a year to replace, so great is the need for these tools in war plants.

Under the heading, “Handle With Care”, the INspection Department gives the following 10 simple suggestions for maintaining our micrometers and other precision tools in perfect condition:

Micrometers and precision gauges are delicate instruments. Handle the as you would a fine watch.

Don’t drop micrometers or gauges on the floor or work bench. If accidentally dropped, precision gauges should be returned to the Gauge Room for inspection before being used again.

Never tap a precision gauge on the edge of the work bench. Even slight jarring will affect its accuracy.

Don’t mix gauges and micrometers with ordinary bench tools. Lay precision tools down gently away from other tools.

Don’t spring or force gauges over the work. THis will damage the gauge and cause the work to be rejected.

Don’t gauge work while the machine is in motion. This strains the gauge and work gauged while in motion is never accurate.

Don’t tamper with the adjustment. Micrometers or gauges no longer accurate should be returned to the Gauge Room for test and adjustment.

Don’t use ordinary machine oil or cutting fluid on micrometers and gauges. All precision tools should be returned to the Gauge Room for inspection and oiling.

Keep gauges and micrometers clean. Perspiration from hot hands will corrode the highly polished surfaces. After using dry with a clean soft cloth.

Return gauges and micrometers promptly when not in use so fellow-workers will not be kept waiting because tools are out of stock.

6

OUR LANCASTER BOMBER PARTS NOW FLY OVER GERMANY

Bomber parts made by Westinghouse war workers in Hamilton went to complete a giant Lancaster bomber last month which by now is helping to blast Germany into submission.

The first of the big Lancaster to be made in Canada, the plane was christened “The Ruhr Express” by Mrs. C. G. Power, wife of Canada’s Minister for Air, at a huge celebration at the Victory Aircraft plant at Malton early in August. Immediately after the ceremony the bomber took off for overseas.

A proud moment for Victory Aircraft workers, the honors were also shared by several of our departments at Hamilton. One of several supplier firms selected to build parts and fittings for the largest of all British heavy bombers, our plant furnished a variety of essential component parts which our years of electrical and manufacturing experience has fitted us to carry out with dispatch.

A condensed list of the equipment being produced for the Lancaster by Canadian Westinghouse includes bomb racks and bomb release mechanism, identification signal boxes, electric circuit terminal blocks, emergency aerial winch and reel, aerial insulators and ice shields, tubes for the transmitting, receiving and inter-communications sets, and flare releases. Our tool room also built special tool and assembly jigs and fixtures for use on assembly work in the Victory AIrcraft plant.

Rated the world’s largest, fastest and most devastating heavy bomber, the first Canadian Lancaster was completed, ready for action, 16 months after the arrival of blue prints from England. To produce a ship of such size in such relatively short time is a feat in itself dwarfed only by the knowledge that this was only the first of a long production line of Lancasters that will now start to roll from Canada’s largest aircraft line.

Exclusive of rivets, nuts and bolts, the Lancaster has more than 50,000 parts and assemblies, not counting the engines and gun turrets. Over 4,000 square feet of aluminum sheets are needed to cover the fuselage and wings, and approximately one million rivets and 14,250 bolts are used in the construction. The huge 69½-foot fuselage is built and assembled in sections, each section being wired and fitted before it reaches the final assembly floor. This unique assembly not only saves time in building the ships but permits sections damaged in action to be quickly replaced by boltin in new sections. THe radio, inter-communication, control and lighting circuits are likewise wired in sections for quick replacement, using hundreds of little Westinghouse-built terminal blocks.

The tremendous size of the Lancaster is apparent in the photos on these pages. From tip to tip the wings measure 102 feet. Seated at his controls the pilot is 18 feet off the ground. The wheels are fix feet six inches in diameter and are retractable. Including the eight ton bomb load, the plane weighs 30 tons. With its four motors, each developing 1,250 horsepower, it can fly 1,000 miles non-stop with a full load of bombs or 3,000 miles with a partial load.

The 69½-foot Lancaster fuselage is built and assembled in sections. The sections arrive on the final assembly floor fitted and wired ready to be joined together. Exclusive of rivets, nuts and bolt,s the plane has 50,000 different assemblies, yet is one of the best aircraft to build from a production standpoint.

The only components of the Lancaster which are not made in the Dominion are the four Rolls Royce Merlin engines which power the 30-ton ship. In flight the wheels are drawn up to increase speed.

7

It was a proud moment for Victory Aircraft workers when the first giant Lancaster bomber to bue built in Canada took to the air recently. Here the huge crowd assembles for the christening ceremony.

Bristling with armament, the big Lancaster has Browning aircraft machine guns mounted in the turrets in the nose, tail, top and belly.

Looking up inside the big 33-foot bomb bay of the Canadian-made Lancaster. Installed in the ceiling are the bomb racks which hold up the eight tons of bombs. Built in our Hamilton plant, the racks are so arranged that bombs may be released a few at a time or all at once! The bomb bay doors open in less than five seconds.

On the instrument panel, immediately below the head of this Victory Aircraft worker, is one of the two Westinghouse-built identification switch boxes on which the crew may tap out the plane’s identification blinker lights should the radio set be damaged.

8

Bird’s - eye view of beautiful Vancouver showing BUrrard Inlet and distant snow-tipped mountains. Westinghouse Officers are located in the Marine Building (left foreground).

VANCOUVER … Pacific Gateway

2,685 miles westward from Head Office in beautiful Vancouver, Westinghouse people conduct the Company’s business with characteristic aggressiveness

When Horace Greeley coined his famous saying, “Go West young man, go West”, he was referring to Pennsylvania, the far West of that day. Nowadays the far West is where the blue Pacific laps the shore and soft trade winds blow. In other words, it’s Vancouver - Gateway to the Pacific.

The city of 400,000 is comparatively young, so much so in fact that it can remember its birth just 57 years ago. Ideally located on Burrard Inlet, the Pacific Gateway is 15 miles north of the international boundary.

These are facts that community-minded people in the Vancouver Offices of Westinghouse will tell you at the drop of a hat. They also have another proud boast. President John R. Read came to Vancouver as Westinghouse District Manager shortly after the offices were opened, and served in that capacity until 1936 when he was appointed Executive Vice-President of the Company.

It was in 1905, just as Vancouver entered the adolescent period at 19 years of age, that Westinghouse opened a small office in Hastings Street. S. B. Smith was the first District Manager.

Many advances in the electrical industry, not a few of which were pioneered by Westinghouse, have taken place since that early date. And in the interval the sales volume of Vancouver Office, on the 14th floor of the imposing Marine Building, has steadily enlarged. Today, with T. H. Crosby as District Manager, the Vancouver Sales Department has successfully adapted itself to provide electrical equipment for a highly diversified industrial set-up. Wartime requirements have brought about an amazing expansion in hydro electric power development, ship-building, lumbering, airplane manufacturing and fishing. Efficient running mate of the Sales Office is the Repair Department, with shop and offices inThe Service Building, 1090 Homer Street. This Department is fully equipped with trained personnel to handle the repairs and renovating of all types of electrical equipment.

Since it has grown from a small hamlet to a large and important metropolitan centre in little more than half a century, future possibilities do not overaw Vancouver. The Gateway to the Pacific confidently expects a post-war business development unparalleled in history. Sharing this vision, and working towards its realization, is the enterprising Vancouver Branch of Canadian Westinghouse.

9

The Warehouse and Service Department Building at 1090 Homer Street houses Service Department SHop and Offices, also facilities for storing and distributing apparatus, merchandise, lamps, etc.

Close up of the Marine Building on the fourteenth floor of which are located our Vancouver Offices. From this vantage point a commanding view of the city is available.

Members of the Sales Office Staff. (Back row, l to r.) Bob Vernon and Bert Robertson. (Front row, l to r.) Muriel Murdock, Lorraine Smith, Gladys Nightingale, Charlotte McDonald and (Mrs.) Agnes Cameron.

Members of the Service and Warehouse Departments recently posed for their picture. (l to r) L. Rimmer, R. Sigurdson, A. Grischuck, N. Dillabough, L. Beal, L. Dohm, W. Millar, R. Jarratt, J. James, G. Lautsch, M. McIsaacs, H. Wilson, W. Thomson, E. Davies, J. Derhousow (absent), J.D. Gregory, W. Ferguson, and L. Marshall.

P. D. Ferguson

Refrigerator Sales

T.M. BLair

Accountant

T. H. Crosby

District Manager

W. Millar

District Engineer

J.A. Tames

Sales Engineer

G.N. Gardner

Appliance and Lighting Sales

F.H. Hedley

Sales Engineer

10

NEWS IN REVIEW

EAST PLANT

General Office- The Service Department had the pleasure of a visit from Tom Eastwood, Foreman of our Service Repair Shop at Winnipeg. Tom was on his way to attend the presentation of Wings to his son, Glenn, formerly one of our employees, at Uplands, on August 6th. Glenn was an apprentice at Hamilton before joining up in March of last year.

Engineering- Joe Thwaites was recently made a member of the Electronics Committee, American Institute of Electrical Engineers. Joe is the only Canadian on the Committee and is to be congratulated on his appointment.

Attractive Thelma Gent rests her horse somewhere along a Wasaga Beach bridle path. THelma, recently back from her vacation, is Editor K.J. Farthing’s secretary.

M4- The girls in this Department were thrilled recently to receive letters from the Women’s Voluntary Services for Civil Defence in London, England, and Belfast, Northern Ireland. THese letters tell the girls of these organizations’ great pleasure in receiving gifts from Canadian donors.

Space will not permit the printing of these letters, but they both convey to all members of M4 Overseas Club very deep appreciation of their generosity, and the Magazine wishes to congratulate Margaret Gray and her energetic committee, who carry on this splendid effort.

D6- Friends of Al Brown, formerly of this Department, who enlisted in April this year in the R.C.A.F., will be sorry to learn that he has contracted infantile paralysis and is at present in Alexandra Hospital at Montreal.

Nine “Western Gentlemen”, herded by Manager Hamilton, and a like number of “City Slickers”, under questionable guidance of Syd Marshall, are making soft ball history for D6, besides a lot of fun for their fans. Selected players from the above teams, “precision ground” and “inspected” by Captain Howard Priest and Coach Carpenter, take this opportunity of throwing down the mitt to any group of “Pill Pounders” who wish to try their luck in getting to first base. So come on with your teams! Try us out.-But keep in mind that when you can’t see it you can’t hit it.

H1-We suffered the loss of one of our fellow workers very unexpectedly on the Civic Holiday week-end, when John Law, who has been an employee of the Department for several years, was drowned at Puslinch Lake on Sunday, August 1st. The sympathy of the Department and other friends is extended to his parents.

Grace Thresher, Secretary to Chairman of the Board, Paul J. Myler, is here shown receiving a beautiful gold watch from her “chief” in recognition of 35 years’ service with the Company. Jack Holk (centre) is PResident of the Senior Veterans’ Association which sponsors such presentations.

Young Dick Skillen, whose father, Pres, is in the Engineering Dept., spent a good part of the summer playing Cowboys and Indians. Now, like scores of other youngsters, he’s back at school studying “readin, ritin, and arithmetic.” The realities of life are tough on little guys.

R3- Congratulations are offered to Jim Mann, Assistant Foreman, Tom Summers, Tool Engineer, and Harry Newton, Supervisor on Brown & Sharpe Automatics, on their recent promotions to these positions in R3.

M1-L1-We have often heard about (Continued on Page 12)

11

Twenty-three years ago these boys comprised a championship team in the Westinghouse Softball League. How many Kings of Swat do you recognize? Legend has it they made up one of the smartest teams ever seen around these parts.

2 LAUGHS

Fat pedestrian (knocked down by a car):

“Couldn’t you have gone around me?”

Motorist: “I wasn’t sure whether I had enough gas left.”

The general was lecturing a class of student officers. “A 40-foot flagpole has fallen down,” he said. “You have a sergeant and a squad of ten men. How do you erect the flagpole again?” The candidates offered suggestions involving a block-and-tackle, derrick and so on. “You’re all wrong,” replied the seasoned officer. “You’d say, ‘Sergeant, get that flagpole up.”

FAMOUS FIGHTER SQUADRON THANKS WESTINGHOUSE PEOPLE FOR CIGARETTES

No. 401 Squadron was First to Fly in Many Fights over Britain and the Continent.

C.N. SALVISBURG, Treasurer of the War Services and Charities Fund has received numerous letters from overseas, thanking our employees for their gifts of cigarettes, etc. One very interesting letter was from Squadron Leader Neal, Officer Commanding, No. 401 Squadron, R.C.A.F., Overseas, which is the Squadron that Henry Sprague, son of VIce-President W.E. Sprague was attached to before being taken prisoner some time ago. Squadron Leader Neal points out that cigarettes purchased in the Old Country are very expensive, about 24c. For ten. Tobacco costs the equivalent of $6.50 a pound, which is a practical reason why our gifts are so welcome and so greatly appreciated.

Famous Squadron

This is rather a famous unit, being the first R.C.A.F. Squadron in action in the Battle of Britain, three years ago. It was first to escort Flying FOrtresses over Europe, first to provide fighter cover over Rotterdam, first Squadron to use the most advanced type of fighters in July, 1942, and the first R.C.A.F. Squadron to engage the Focke-Wulfe 190 Fighters. The Squadron has a total credit of 56 enemy aircraft destroyed and over 100 probably destroyed or damaged.

Our little monthly contributions are helping to keep these splendid representatives of our country in good spirits, and the little we contribute is not missed by any of us.

We have been asked by A.L. Meynell, Secretary of the Senior Veteran Employees’ Association, to invite any eligible employee to join this Association. Please communicate with him at The Benefit Department, Works Office.

“Injury”, said the workman.

“Inattention”, said the foreman,

“Inflammation”, said the physician.

“Incurable”, said the hospital.

“Incredible”, said the mourners.

“Interred”, said the undertaker.

“In Peace”, said the tombstone.

When the word got around that three of their fellow-workers, (l to r) Tom Shimmell, John Bull and Bob Gavey were retiring, members of the Foundry tendered them a dinner and social evening which was enjoyed by all present. Combined service records of the Old-Timers total 73 years. (See story on page 13)

12

…the big one that got away, but Russ Bea (M1) not only let the big one get away, but his line, rod, reel and a two dollar spinner went with it. We are all wondering how Russ is going to explain the loss to his brother-in-law, the late owner of the aforementioned equipment.

Every day Westinghouse Main Office elevators travel about four miles in taking passengers to and from their offices. When it seems that an elevator will never come, be patient. Maybe, like this one in charge of Doris Ellis, they are delivering other busy war workers to all seven floors.

Going UP!

“Going Up,'' sings Lois Pickard and a few seconds later her elevator was filled to capacity. Don’t be like one passenger who said “Oh, three please” just as Lois “landed” at the fifth floor. Call your floor early.

F-7-The Ladies’ Soft Ball Teams of F7 and F` got together on Friday evening, August 6th and had a very enjoyable time. P.S.-Your editor hopes that at his gathering it was decided which was the better team.

This is the Westinghouse championship relay team, members of which streaked past the tape to take first place in the Industrial Relay Race event at the Hamilton Police Meet on July 1st. On August 21st the same team won the Open Industrial 440-yard relay at the Buffalo Uniformed Firemen’s Meet for the fifth straight year. (l to r) Tom Dumbill, Doug Cousins, Mike Katz, Arnold Dafoe, Dave Strang and Jim Honrsby; (inset) Bill Champagne.

F1-The sympathy of all members of this Department is extended to Mrs. Bonnallie, of Mount Hamilton, whose son was drowned on July 29th at Wasaga Beach. William was admired by everyone in this Department and always had a smile which will be long remembered.

A draw was recently held in this Department in aid of the Greek Relief Fund, and the sum of $56.00 raised. This opportunity is taken to thank all who made this event an outstanding success.

Our ball team played the White Air Craft on August 5th at Mahoney Park: Score: F1 Dept.-12; White Air Craft-10.

Q Department- Sam Taylor, of this Department, who recently received his Wings at Brantford, was commissioned as a Pilot Officer, and the congratulations of this Department go forward to him.

BX and B7 should be proud of its members who are members of the Voluntary Blood Donors Group. Over 120 donations have been given by 26 members of these Departments. Your editor regrets that space does not permit the printing of all names. Special mention, however, must be made of Albert Boult, Frank Jones, Wes Houston and Jim Brown, who are mainly responsible for the splendid record achieved.

WEST PLANT

WJ1-Berg Clegg, draughtsman in the Illumination Division is back on the job again after being dangerously ill for several weeks. We are very glad to see you back, Bert.

His friends in the East PLant will be interested to know that Sam McKNight, formerly of the Engineering Department, is now with us in Department WJ1.

WD2-On behalf of members of the Lamp Engineering Department, we extend our sympathy to Carman Cantlon, whose mother passed away recently at Seaforth. Also to James Radcliffe, Pipe Fitter (WD2) who lost his wife on July 31st.

13

Here is LEading Air Woman Bessie Tunstead who enlisted in December, 1942. ‘Member when Bessie was a Timekeeper in F7?

WD1-The numerous friends of Jessie MacNaughton, who for years was an employee of this Department, will be pleased to hear of her safe arrival overseas. Jessie, who is a daughter of Tom MacNaughton, (Department H, East Plant,) is a Lieut. Nursing Sister with No. 13 Canadian General Hospital, which is under the command of Lt.-Col. L.A. Carr, M.D., of this city. She has already seen considerable service, having been with the R.C.A.M.C. for over 2½ years.

Congratulations to Geroge Horbett, who, on July 31st, joined the R.C.A.F. and is now stationed at Manning Pool, Toronto. George was presented with a purse as a farewell gift.

WX-Distinguished visitors to this Department recently were: Representatives of the Chinese Government, G.W. Chu, M.C. Tung, E.N. Yen and R.C. Lynn. They were accompanied by representatives of the Westinghouse International Company from U.S. Also Petty Officer Arnold War, R.C.N., previously foreman of Planers, WX.

Foundry News- Tom Shimmell, John Bull and Bov Gavey were tendered a farewell dinner by their fellow employees at the Royal Connaught Hotel on July 30th. Having each attained the age of 70 years and being eligible to retire under the company pension provision, their friends thought they should be honored, and organized this entertainment. John Bull, under ordinary circumstances, should have retired in December, 1942; and Bob Gavey in October of this year; but owing to the war these two have now decided to carry on for the duration doing their share to hasten Victory. Tom Shimmell who was recently advised by his physician that a rest was essential, received from the hands of Vice-President C.H. Mitchell a signet ring, as a token of the esteem in which he is held by Foundry men and other employees who gathered to pay a merited tribute to these three Westinghouse veterans. A very pleasing program was arranged by George Green, who capably acted as Chairman for the evening.

DISTRICT OFFICES

TORONTO- Friends of Captain Rolly Cleworth, formerly of Swastika Office will be interested to know that his name is mentioned in press dispatches as being one of the officers in the Cliff Assault in a recent campaign in Sicily. His regiment clambered up a 2,500 foot precipice and stormed a crest in a pre-dawn attack, capturing the town of Assoro.

Ever see a fireless engine? This one does yeoman duty in the West Plant yards every day of the week .Twice a day it is charged with sufficient steam at the boiler house to ensure operation for four hours. Charlie Mace, World War 2 veteran is at the controls.

14

Here comes the bride in the person of Ruth (Strathmann) Long (centre) who before her recent marriage worked in the Correspondence Department. THelma Gent (same Dept.) stands to the left of the bride as a bride’s maid.

WINNIPEG- We regret to record the death of David Stewart, formerly Shipper in our Winnipeg Branch, on Monday, July 12th. He retired in 1936, due to ill health, after faithfully serving as Winnipeg’s Shipper for thirty years. To his wife and son, we offer our heart-felt sympathy. Davie will be long remembered by us all.

We are pleased to renew acquaintances with Gorgon Finch, of our Ottawa Office, who visited Winnipeg during July while on holidays in the West. Gordon formerly worked here and in Calgary, and is well known in these parts.

Your reporter had the opportunity of saying “Hello” to Walt. Baylis, en route from Hamilton Office to Calgary Office to take on new duties there. Winnipeg staff is ready to give you any help that might be required, Walter, and wishes you the best of luck.

This sturdy soldier is Fred Marshall of “A” Squadron, Tank Corps, Camp Borden. Soldiers like Fred, who used to work in K4, are loud in their praise of Westinghouse people who keep them well supplied with war equipment. Fred’s Dad carries on that at the plant.

BRIDES AND GROOMS

Irene Walton (F1) to AC2 Reg. Bovaird, on July 9th, at Hamilton.

Marie Lowriss (F1) to LAC George Kennedy, on July 17th at Hamilton.

Marjorie Sharp (WD1) to Joe Campbell (R1), on July 24th at Hamilton.

Ella WHitney (R1) to Mike Kohan (F1), on July 31st at Hamilton.

Margorie Cardno (F1) to Harold Race, on July 31st, at Hamilton.

Dorothy Cooper (WD1) to A.B. (Bill) Heinhold, R.C.N.V.R., on August 9th at Hamilton.

Betty Jones, Comptroller’s Department, to William Davies (WD1-WD2), on August 14th at Hamilton.

Dorothy WIllis (WD2) to LAC Hugh Morgan, R.A.F. of Wales, on August 14th at Hamilton.

Muriel Willson (WD1) to Archie Davey, on August 21st at Hamilton.

Do you know?

A submarine’s maximum speed under water is 11 knots. Running at this speed it will use up batteries in an hour. At a speed of 3 or 4 knots the submarine can go 24 hours without recharging batteries, which it can only do by coming to the surface.

Half-a-million man-hours and many, many tons of critical materials have been saved by employees of one firm alone through suggestions of its employees. Employees of this firm-Westinghouse Electric Company- turned 22,788 ideas, of which 7,365 were put to use.

More than 23 railway tank cars of heavy fuel are needed to supply a single destroyer on a round-trip between the East Coast of Canada and North Africa.

Westinghouse at Vancouver has a sub-office in Trail, B.C. ably presided over by B. James (above) His attractive daughter looks after the secretarial work.

NEW ARRIVALS

To Tom (D6) and Mrs. Hulme, on May 23rd, a daughter, Anne Elizabeth.

To Rodger (M4) and Mrs. Woodcroft, on July 6th, a daughter, Mary Olef.